Miyota mechanical movements

Miyota's mechanical movements are designed with high precision and durability in mind, just like our quartz watches. What’s more, they can be mass-produced using the techniques developed for manufacturing analog quartz movements.

The Caliber 8200 series became the most widespread mechanical movement in the world and we have supplied it for watch brands around the world. As is true of analog quartz movements, there are only a few companies in Japan that can manufacture mechanical movements.

The vast majority of watches sold today are analog quartz. Mechanical movements, on the other hand, are more expensive and time-consuming to produce, but are valued for their craftsmanship, artistry and beauty. Mechanical watches, and especially automatic watches, are sometimes handed down for generations as heirlooms.

History of the development

of Miyota’s mechanical movements

The manufacture of Miyota’s mechanical movements

At the Iida Factory, we are using automatic assembly lines that make full use of the latest labor-saving technology to assemble mechanical movements.

1Movement automatic assembly line process

Assembly

Parts assembly, screw tightening, oiling

Inspection

We perform various inspections, such as for height, screw tightening torque, missing parts and damage, with one process per location.

Assembly line

We assemble our mechanical movements using lines that incorporate our expertise in movement mass production. Our fully automated assembly lines are made possible by precision parts processing technology and our proprietary assembly devices that operate with high precision.

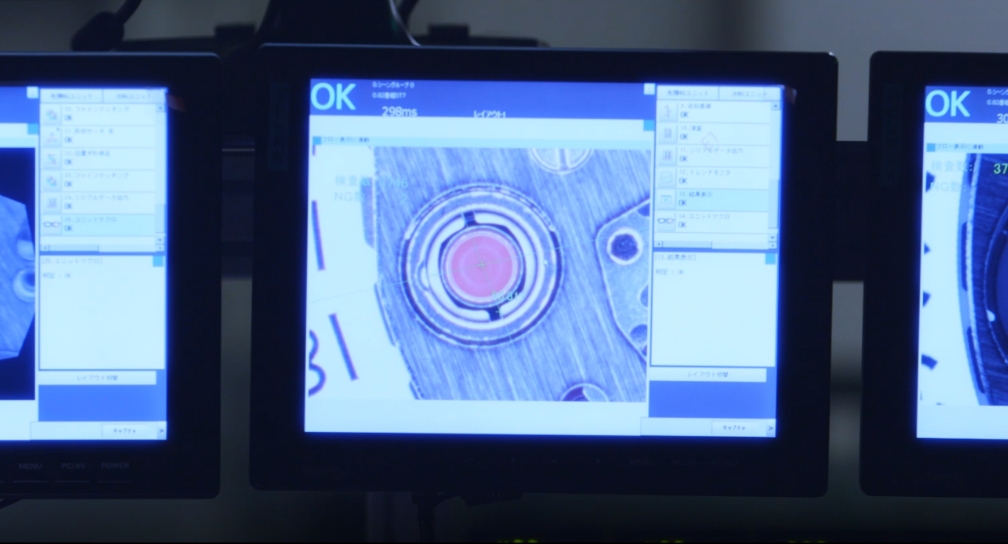

Automatic exterior check

In recent years we have been computerizing them as well. We perform various inspections of the parts of our movements. A specialized computer is used to analyze photos taken with a digital camera and detect flaws such as missing parts and major damage. When a problem is detected, the part is automatically removed from the assembly line.

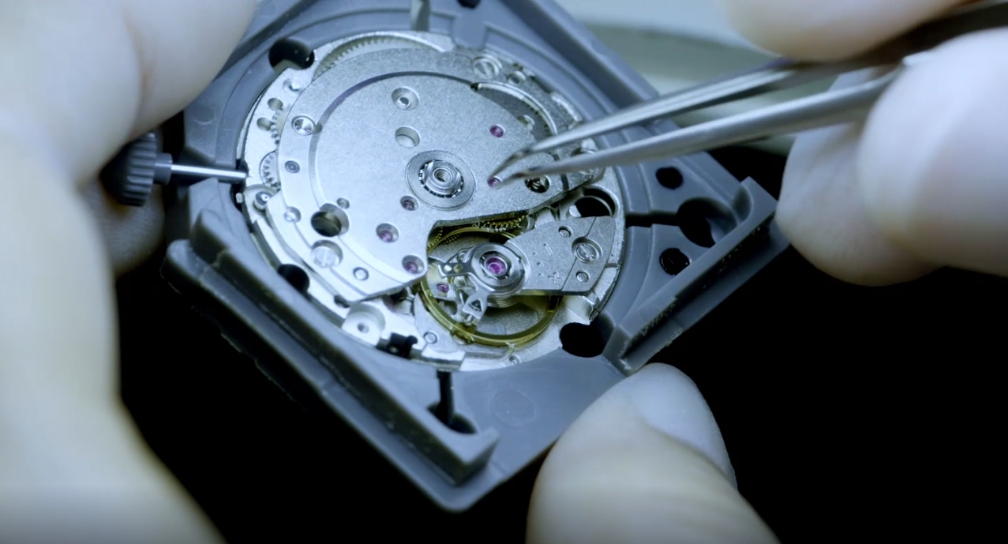

Exterior quality check

In addition, at various intermediate stages in assembly, workers use microscopes to inspect the parts being put together.

Balance check

Even though it's a hand assembly process, insertion of the balance, a nerve-wracking process, is automated. Part checking is essential here as well.

Assembly of Oscillating Weight

Oscillating weight movement check

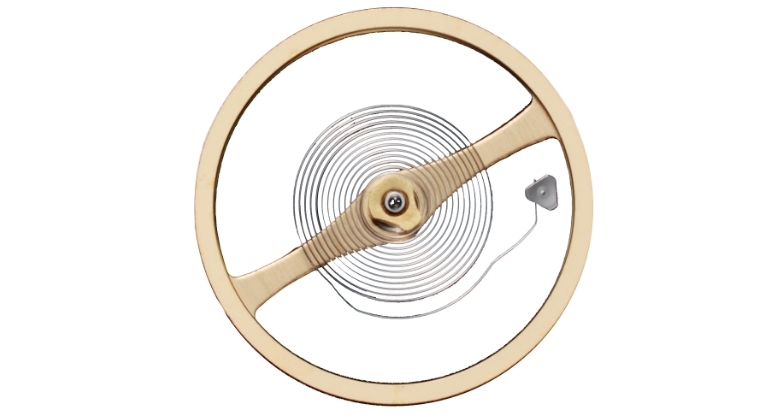

1Balance wheel

We have adopted some streamlining measures, but our balance wheels are produced by human hands. Adjusting the eccentricity and horizontality of the balance spring is the most difficult procedure. Technique that cannot be expressed in numerical form is required.

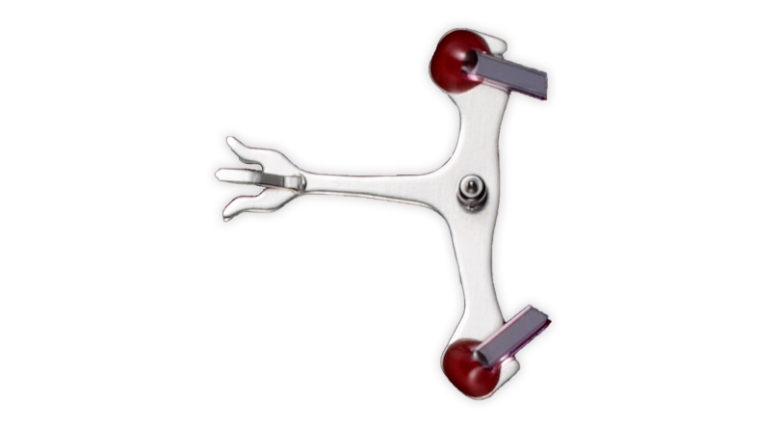

2Jeweled pallet fork and staff

The jeweled pallet fork and staff part of the escapement is another example. It is the size of a grain of rice yet contains five parts.

Miyota’s mechanical movements lineup

Standard Automatic

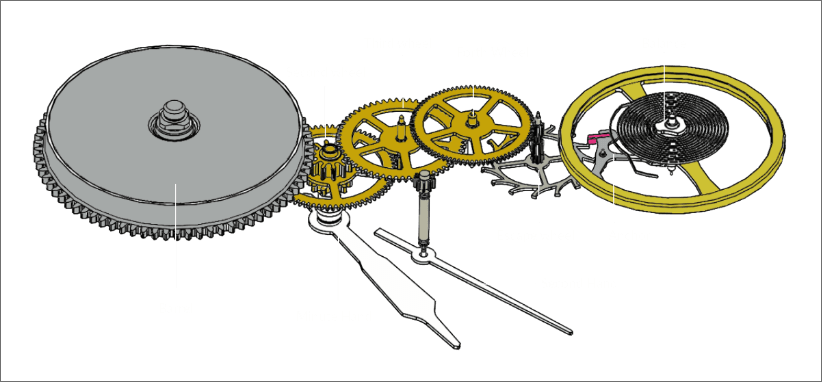

The workings of a mechanical movement

A mechanical movement uses a mainspring as a dynamic force and governs it with a balance. Using the power of the wound mainspring trying to return to its starting point, the ratchet wheel that contains the mainspring rotates, and in turn the dynamic force is conveyed to the center wheel (with the minutes' hand attached), the third wheel and the fourth wheel. The revolution of the escape wheel that is in mesh with the fourth wheel is conveyed to the pallet, and the pallet causes the balance to move left and right. The balance moves in a fixed cycle, so the pallet moves in accordance with it. The balance is the heart of the watch that holds the key to its accuracy. The pallet stops the vigorous force of the mainspring trying to return to its original state and controls the movement of the escape wheel. Also, the pallet and escape wheel are called the escapement.

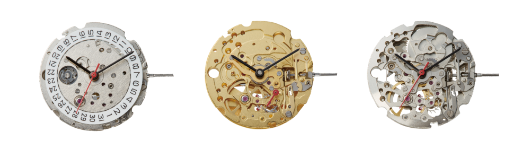

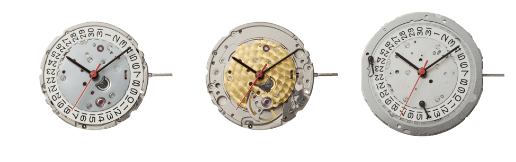

The Caliber 8200 series. This is a long-selling Miyota caliber that has been supplied for approximately 40 years and continues to be supplied today. Its main plates and other parts are manufactured in factories in Japan, and the movements are assembled automatically and mass-produced. Almost all calibers in this series are available in the colors silver and gold.

They have beautiful train wheels and are recommended for creating rear skeleton watches. Open heart watches have a hole at the 7 o’clock position showing the movement of the balance wheel. Mechanical movement fans like this feature. The same is true of skeleton watches, which reveal the entire mechanical structure of the movement. Miyota’s standard mechanical movements use indirect seconds.

Click here for Standard Automatic movementsPremium Automatic

The Caliber 9000 and 9100 series. These movements are in the mid to high price range. They are thin — just 3.9 mm — and boast a polished sense of tension and extreme functional beauty.

Miyota’s premium mechanical movements use direct seconds.

Caliber 90S5 — With an ornamental surface and open heart, this movement allows manufacturers to create designs that show the inner workings of a watch.

Complication — This is the most complex of Miyota’s mechanical calibers. It allows the design of quite thin wristwatches for a multiple-hand mechanical movement. The calendar part of the movement is put together by hand at our factory.