MIYOTA Caliber 90 Series

The New Standard in Premium

Mechanical Movements

Forging a new path for

premium mechanical movements

What are watch brands looking for in a mechanical movement?

MIYOTA has answered that question in a way

that only an integrated manufacturer can.

With the MIYOTA Caliber 90 Series.

Quickly establishing itself as a new standard in the market,

the Caliber 90 Series continues to evolve to this day.

From the start of its development, MIYOTA was determined

to put conventional industry wisdom to one side

and forge a new path for premium mechanical movements.

EPISODE 1 The movement the zeitgeist demands MIYOTA Caliber 90 Series

A new champion in the mechanical movement space

It’s the first decade of the 21st century. Watch brands keen to produce authentic mechanical watches for a contemporary audience were facing a major manufacturing bottleneck in having to rely exclusively on Swiss-made movements. As well as being expensive, Swiss-made movements were often in limited supply. Watch brands were justifiably anxious about securing stable access to a key component.

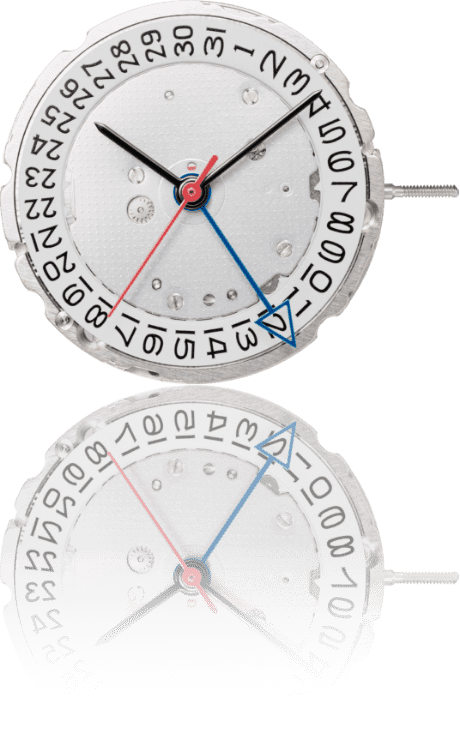

What industry players wanted was a steady, reliable supply of mechanical movements over the long term. Whether those movements were Swiss-made or not was a matter of indifference to them. It was in response to that demand that MIYOTA set about developing a thin premium mechanical movement capable of becoming a new industry standard. After two years of intense R&D, we released the MIYOTA Caliber 9015 in 2009, our first new mechanical movement for 30 years. Appreciative of the new possibilities it opened up, watch brands worldwide hailed the Caliber 9015 as a new champion in the mechanical movement space.

Combining thinness and strength at the very highest level

In developing the Caliber 90 Series, MIYOTA had to confront all sorts of new challenges. The biggest of these was making sure the movement could achieve robustness despite the thinness of its profile. Manufacturing a movement that is thinner than normal is simple and straightforward enough. But if you end up with something so structurally fragile that only a handful of veteran craftspeople can handle it safely, then you’re wasting people’s time. The approach MIYOTA took was to rethink movement production technology from scratch and maximize the precision of every individual part to achieve thinness. By doing this, we were able to come up with a manufacturing process that delivered a level of robustness and durability that ensured a broader cross-section of technicians could handle the movement without difficulty. Through a whole series of proof-of-concept tests, we were able to standardize the thickness of the base caliber at 3.9mm. The end result of all these efforts was a movement that combines thinness and strength at the very highest level.

There are things that only an integrated manufacturer can do

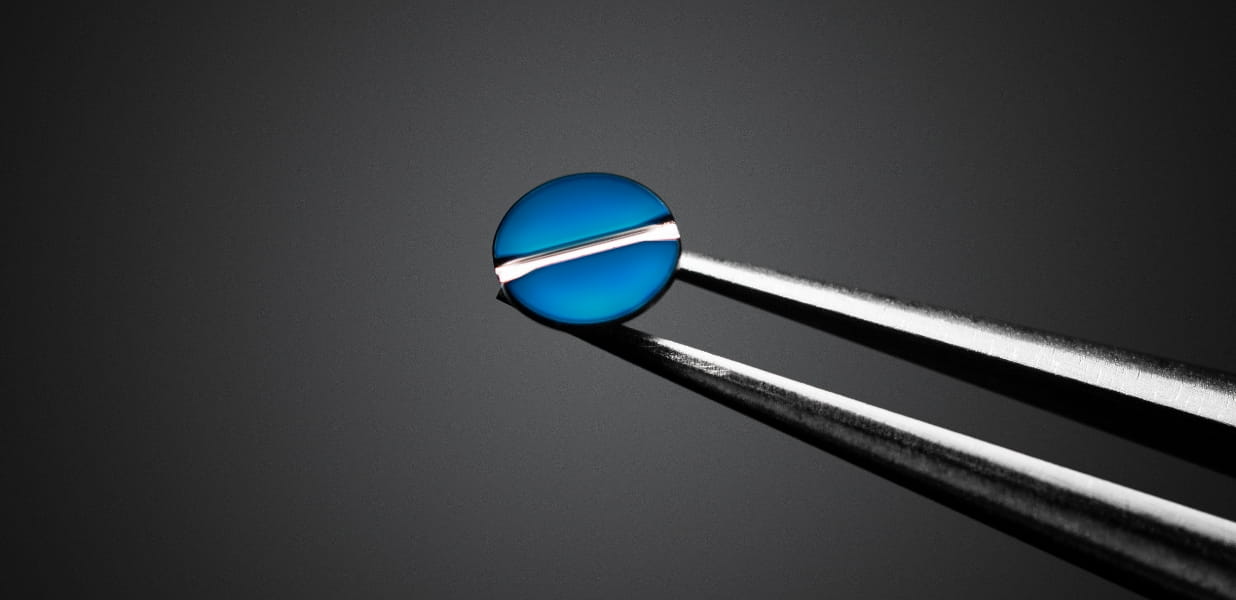

How did we succeed in creating a movement with this unique combination of thinness and strength? The fact that MIYOTA is an integrated manufacturer is certainly one answer to that question. From screws through to gears, balance wheels and hairsprings, we develop and manufacture almost all the parts that go into our movements in-house. (In particular, the number of manufacturers capable of making their own hairsprings is vanishingly small.) At MIYOTA, we design, manufacture and manage every single component with micron-level precision before assembling all these ultra-precise parts into finished movements. The upshot is a system of stable mass-production for movements that are simultaneously robust and thin.

The road to multifunctionality.

The road to True GMT

The Caliber 90 Series has evolved since its 2009 launch. In 2010, we released the Caliber 91 line whose various functions included a power reserve indicator. This caliber ignited a vogue for mechanical watches among young, independent brands eager to create bold statement designs. In 2021, we released the Caliber 9075. Most unusually for a premium mechanical movement made for the general market, the Caliber 9075 has a “True GMT” or “Traveler GMT” mechanism. Not only was the Caliber 9075 well received by brands committed to making authentic mechanical watches, it also contributed to the expansion of the overall market.

EPISODE 2 A New Flagship Caliber 9075 True GMT

Fanatical attention to detail in every single component

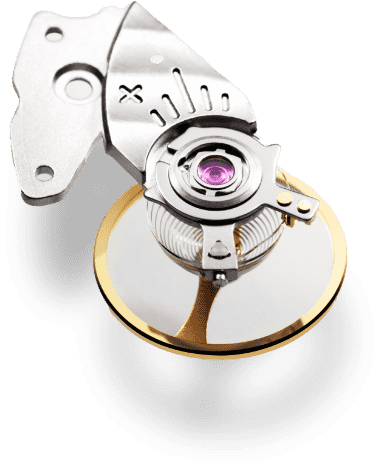

Among mechanical watch movements, True GMT stands in a class of its own. Until very recently, no third-party supplier anywhere in the world was making a True GMT movement (defined as a movement whose local/12-hour hand can be set independently). As a result, watch brands which did not make their own movements in-house were excluded from the True GMT space. MIYOTA set out to break this logjam by launching an R&D blitz that tapped into the know-how and mastery of ultra-precise component manufacturing that we had built up over decades as an integrated manufacturer. The 2021 release of the Caliber 9075 equipped with a True GMT function was the end result. Eagerly awaited by watch brands around the world, the Caliber 9075 quickly established itself as MIYOTA’s flagship movement.

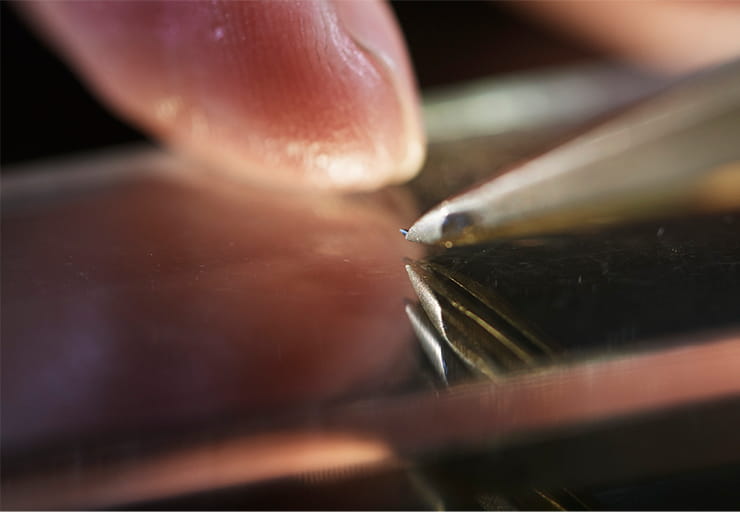

Achieving that satisfying click feel

One of the most endearing features of a True GMT watch is the satisfying “click feel” that you get when setting the time. With the Caliber 9075, we were determined to make the tactile experience as fulfilling as possible. At the design stage, we created and refined countless prototypes in order to achieve the same gratifyingly high-end feel when rotating the crown in both a clockwise and a counterclockwise direction. At MIYOTA, we know that attention to every tiny detail is the only true path to manufacturing excellence.

A movement that fuses easily with the design of the watch

It is only when the movement has been fitted that a watch becomes a finished product. When we were designing the Caliber 9075, we made the most minute calculations to determine the optimum position for the hands and the winding stem. That is why the design of the Caliber 9075 is such a natural and easy fit for the finished watch. The Caliber 9075 is a truly one-of-a-kind mechanism and a source of inspiration for watch designers the world over.

EPISODE 3 Beautiful-looking and long-lasting Heat-blued screws

A rich color that does not fade with time

We want the parts that make up our movements to look good and be durable as well. That is the reason why we offer heat-blued screws as an option for the Caliber 90 Series. As the name makes clear, heat-blued screws are screws that are heat-treated at a very high temperature and then tempered, with the blue color being an oxide layer. At MIYOTA, we use a patented version of bluing technology to give our screws greater longevity and prevent degradation in the form of rusting or fading. MIYOTA craftsmanship means a fanatical attention to every small detail that enables watch brands to produce watches customers will never fall out of love with.