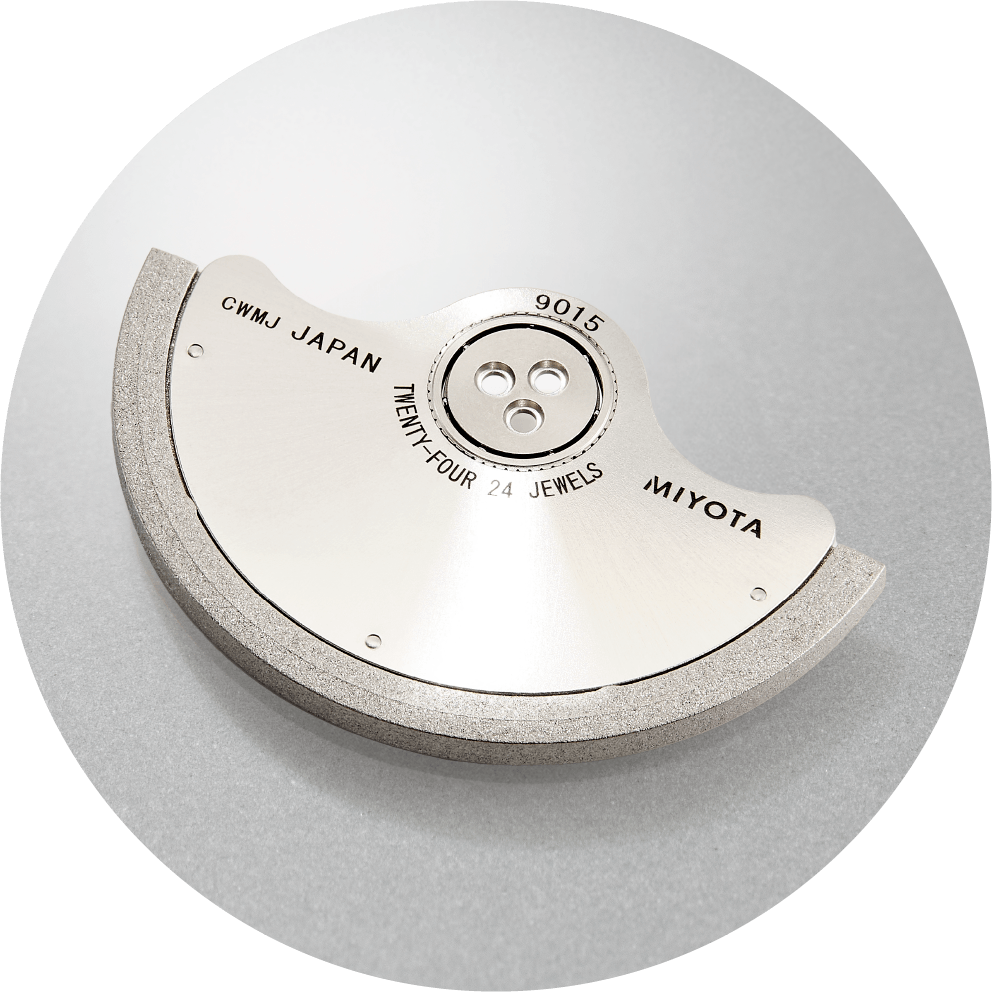

BARRELS COMPLETE

The reason why we still use

a 50-year-old machine today.

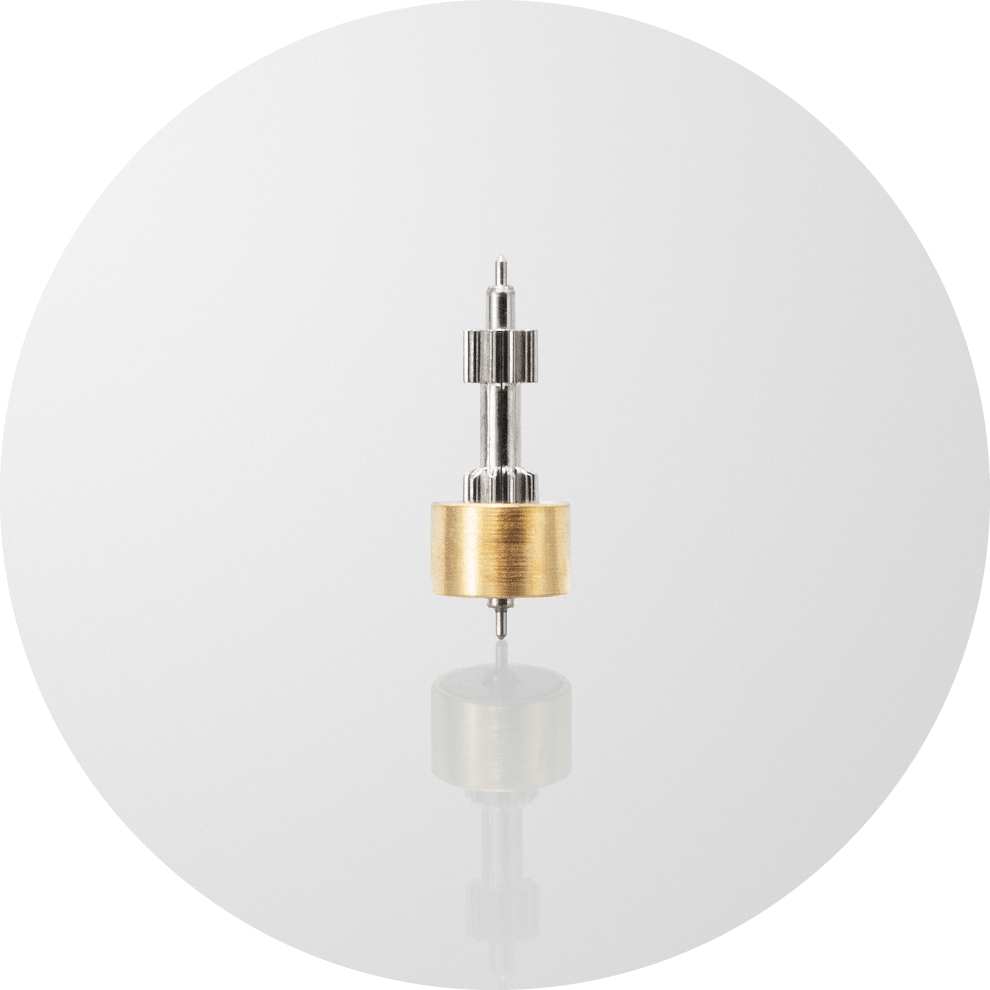

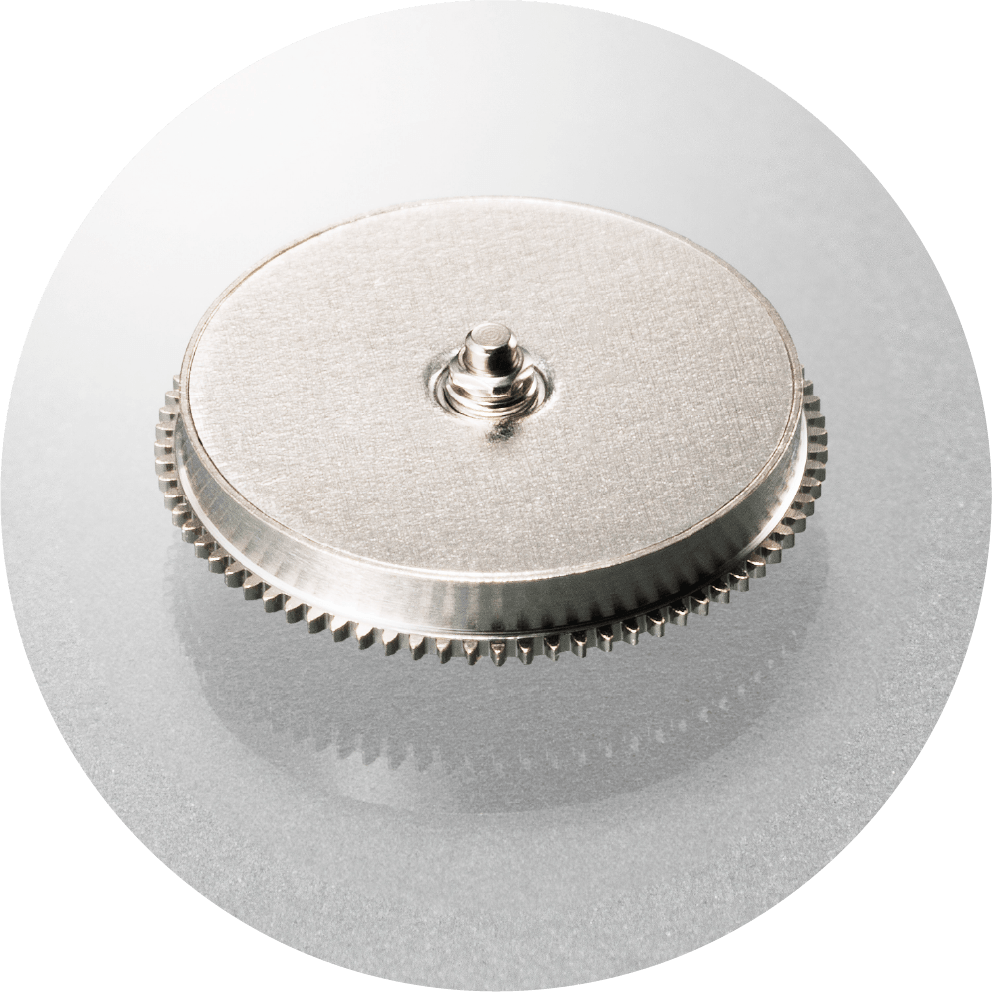

The barrel complete houses the coiled

mainspring that drives the watch.

The barrel complete needs to be highly durable

because the mainspring is wound and unwound repeatedly.

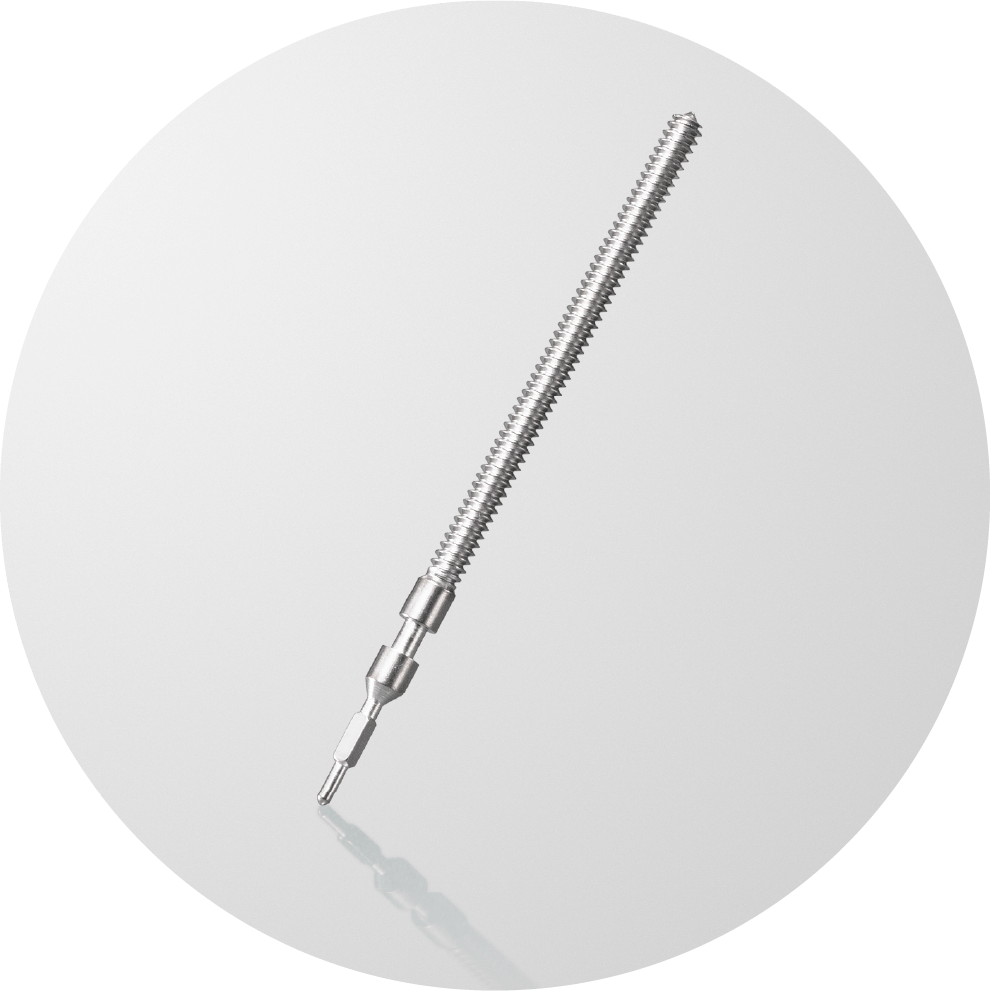

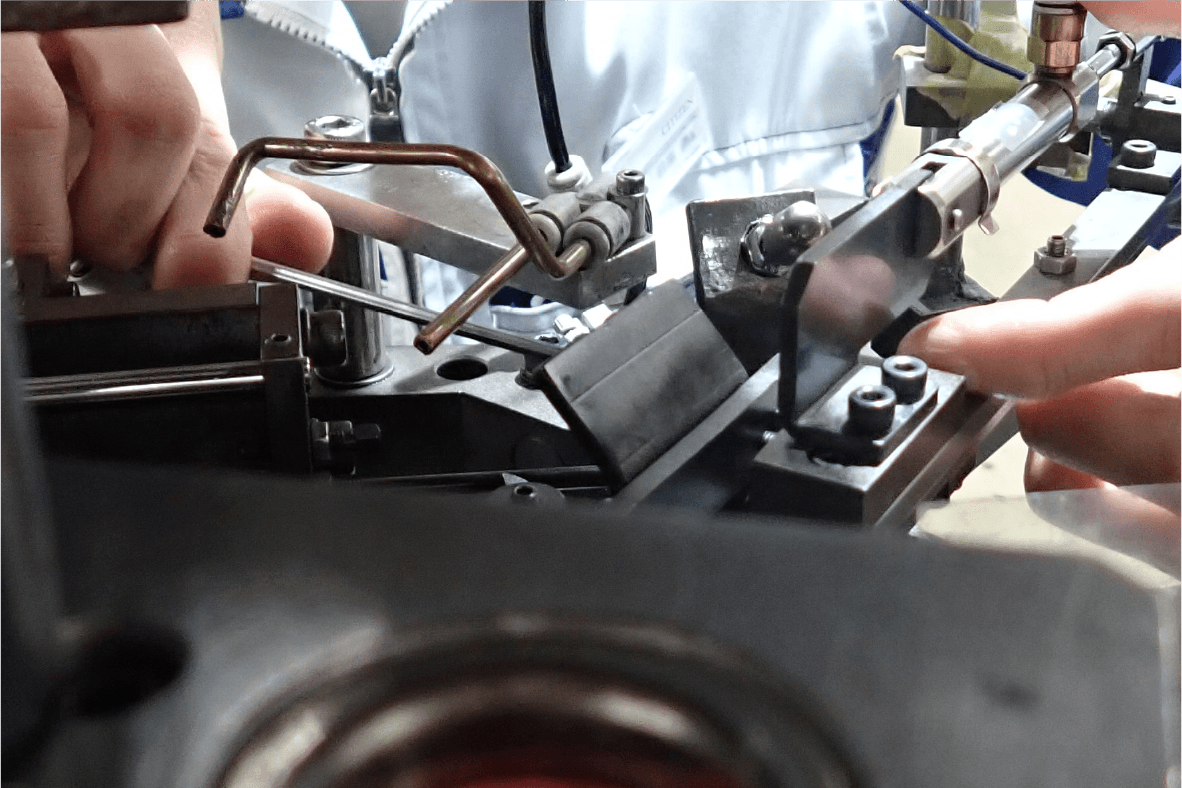

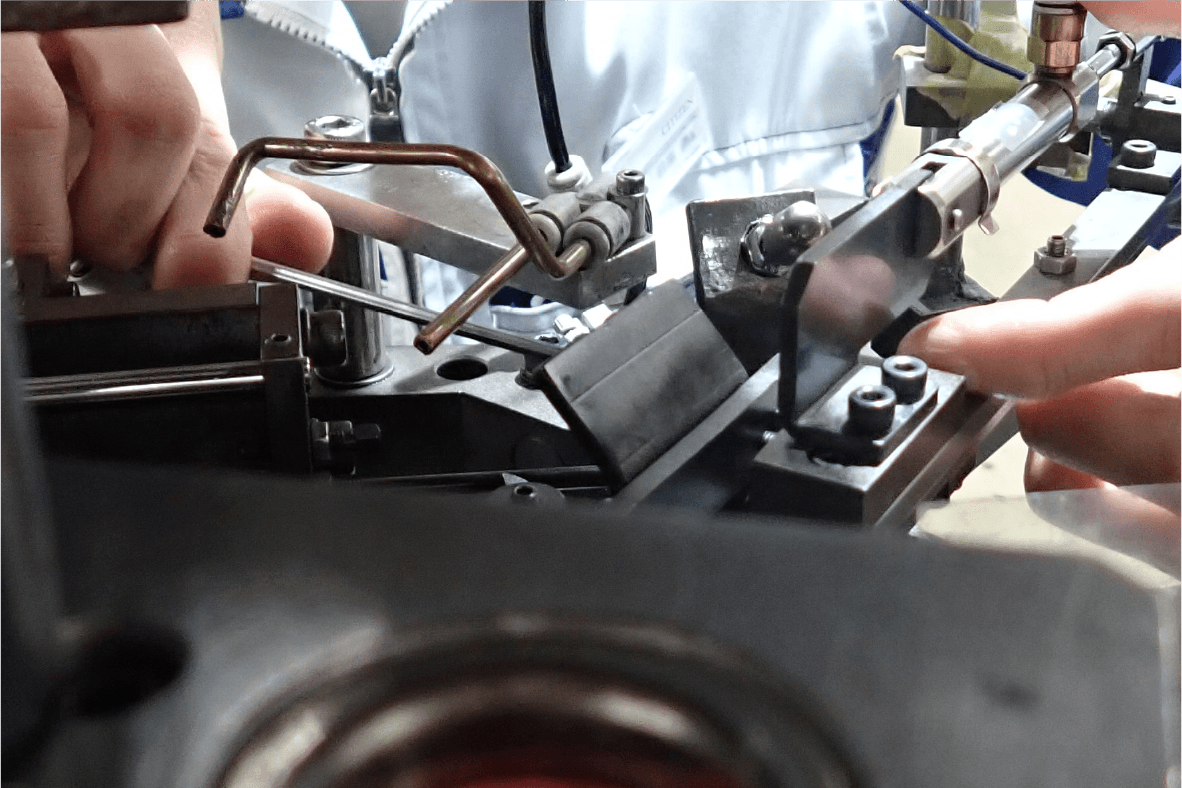

At MIYOTA, we use a single mainspring-processing machine to coil,

weld and cut all our mainsprings.

Although—or perhaps because—this particular machine was

designed and built roughly half a century ago,

it is the repository of the cumulative wisdom and know-how of

previous generations of MIYOTA engineers.

The machine is regularly overhauled.

This enables to us to implement a best-in-class production system,

in which areas that require upgrading are continuously upgraded

while the old methods that do not need changing are

scrupulously maintained and passed down.

This hybrid approach, melding old and new,

is not only one of the great charms of the watchmaking process,

it also explains why MIYOTA maintains such elevated quality levels.

Achieving the right mainspring thickness

and the right temperature for heat treatment are both crucial

for attaining good spring performance.

We use a range of techniques to ensure

that the heat treatment is uniform and consistent.

For instance, we have optimized the layout of the heaters in the furnace

so the temperature is the same regardless of placement.

The wisdom, know-how and meticulous attention

to detail of our predecessors at MIYOTA is a precious legacy

which we have inherited—and which we continue to refine upon.