GEARS

Micron units are

routine for MIYOTA

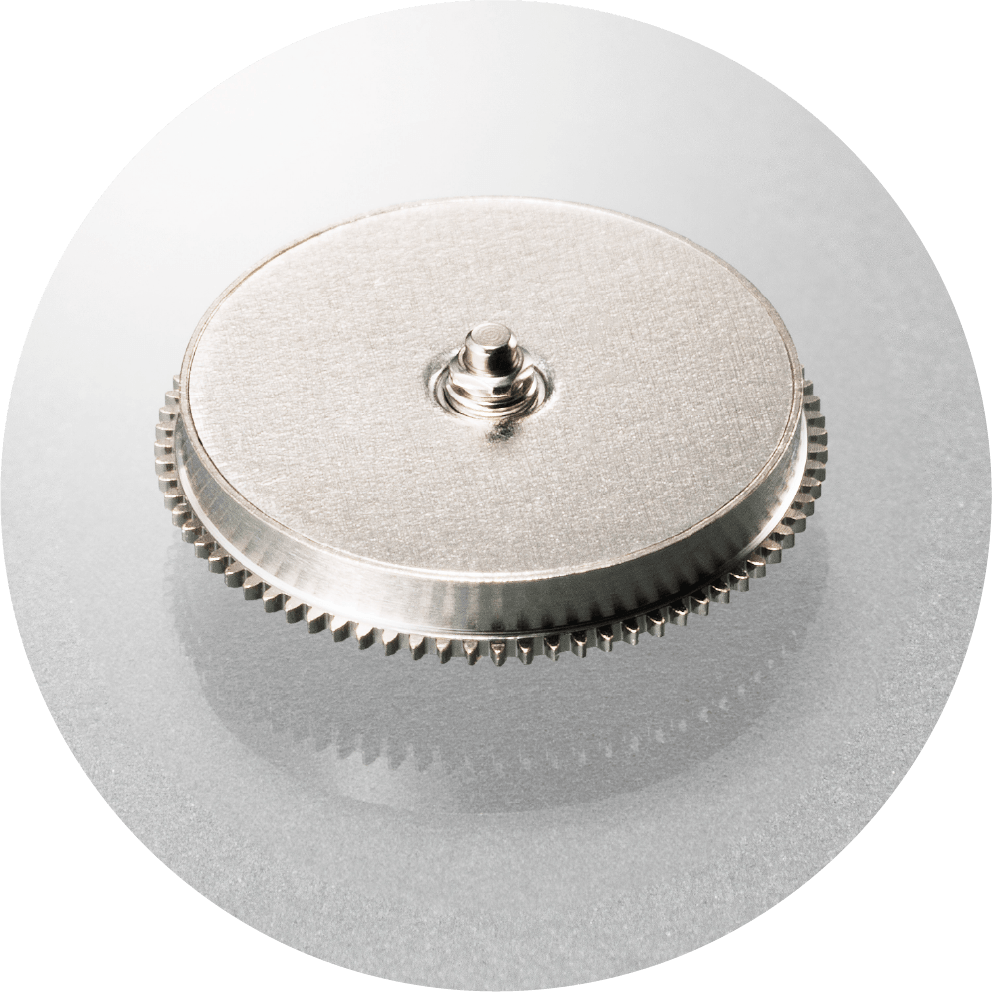

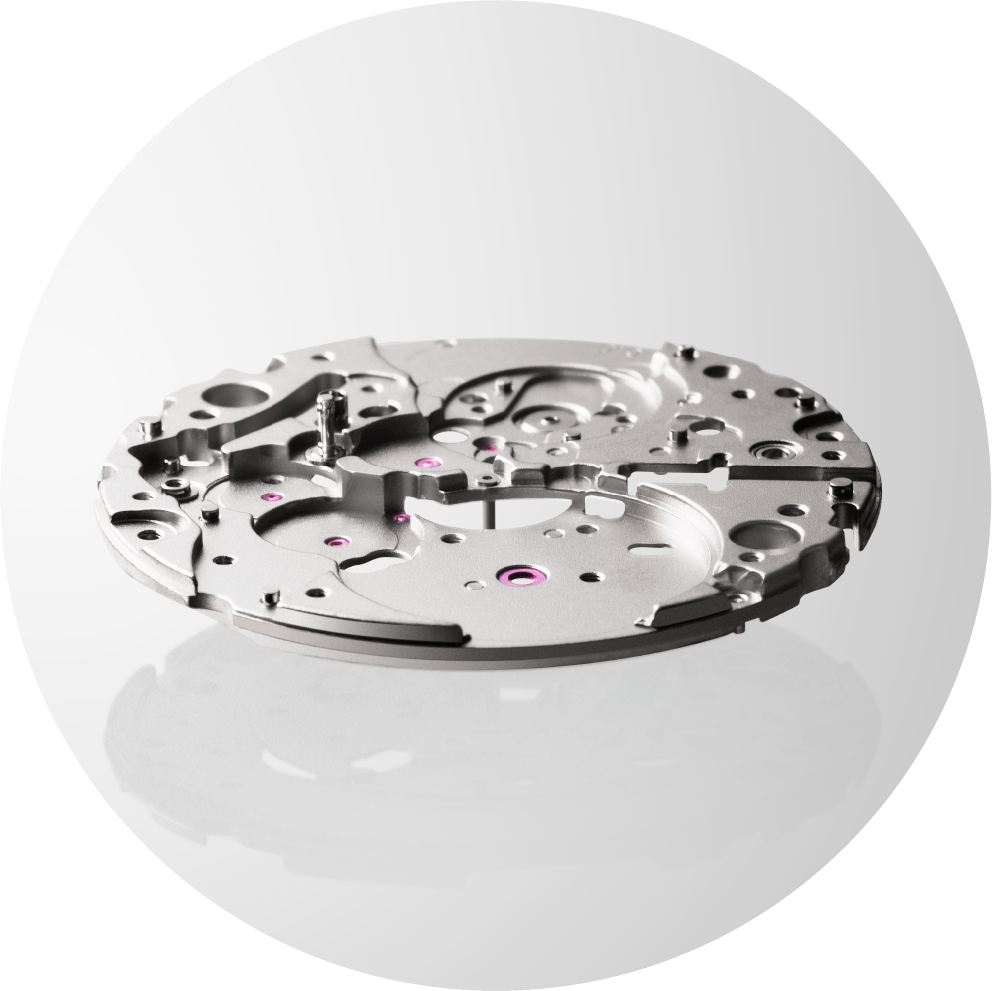

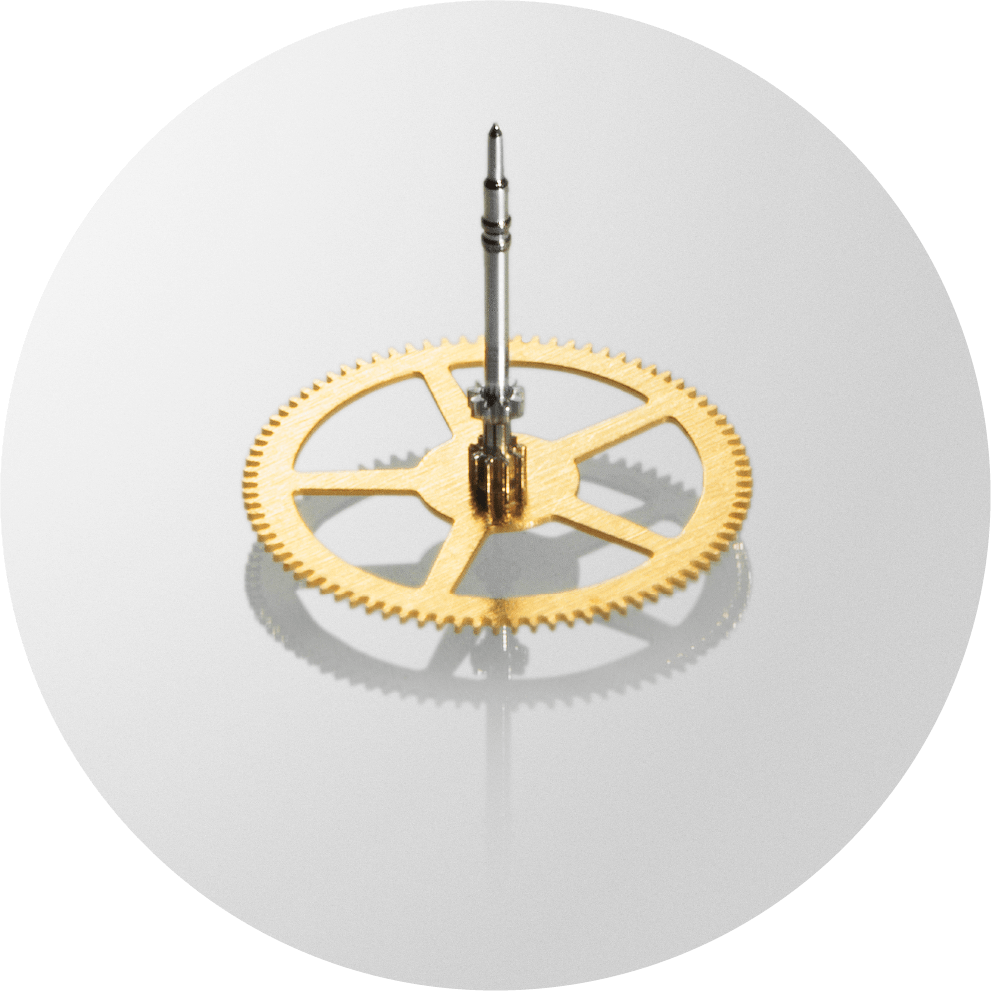

The energy generated by the mainspring or

power cell is transmitted through the gears

that make up the gear train to move the hands

of the watch.

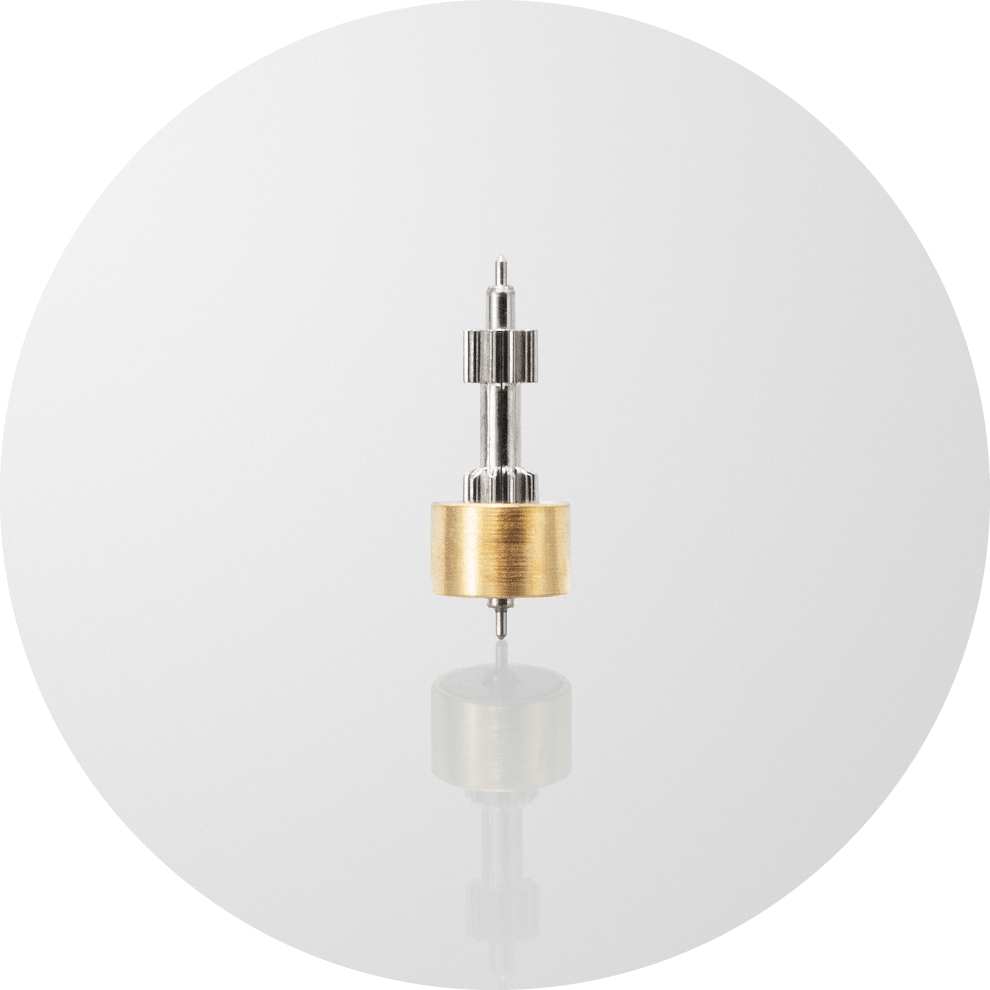

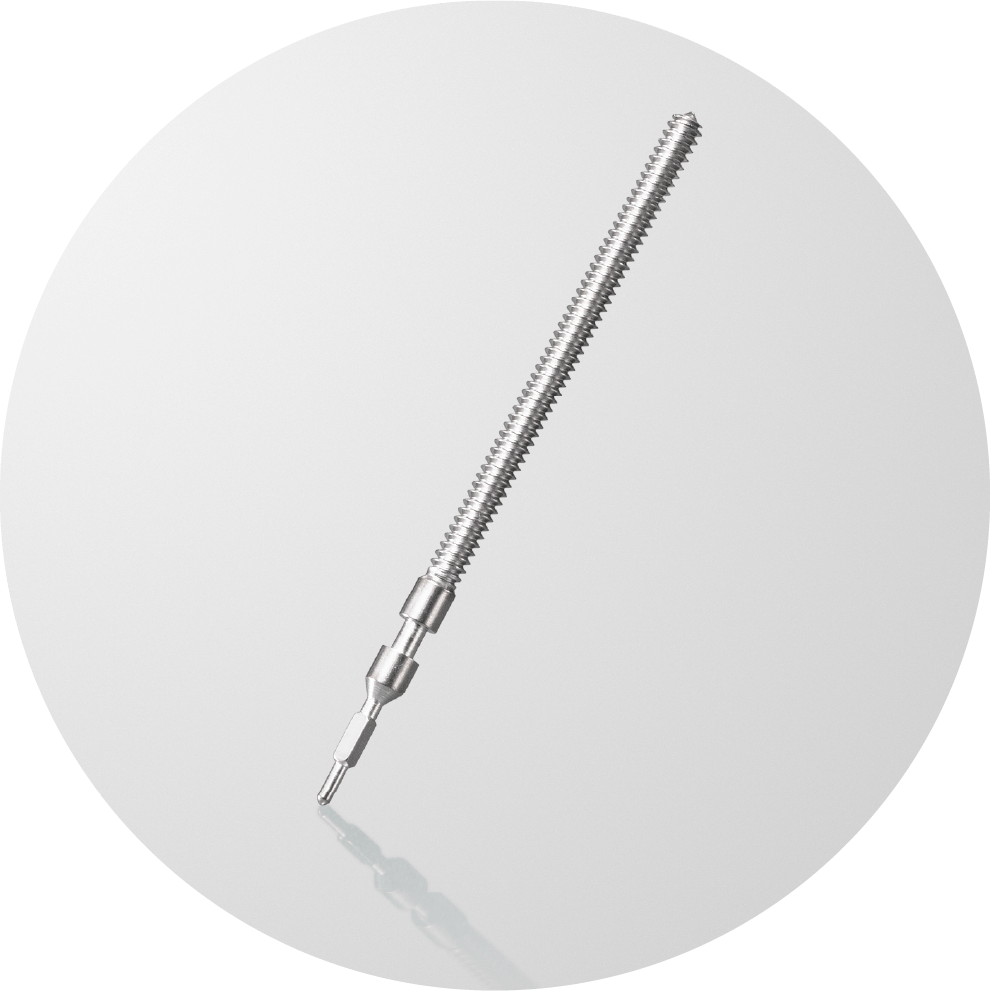

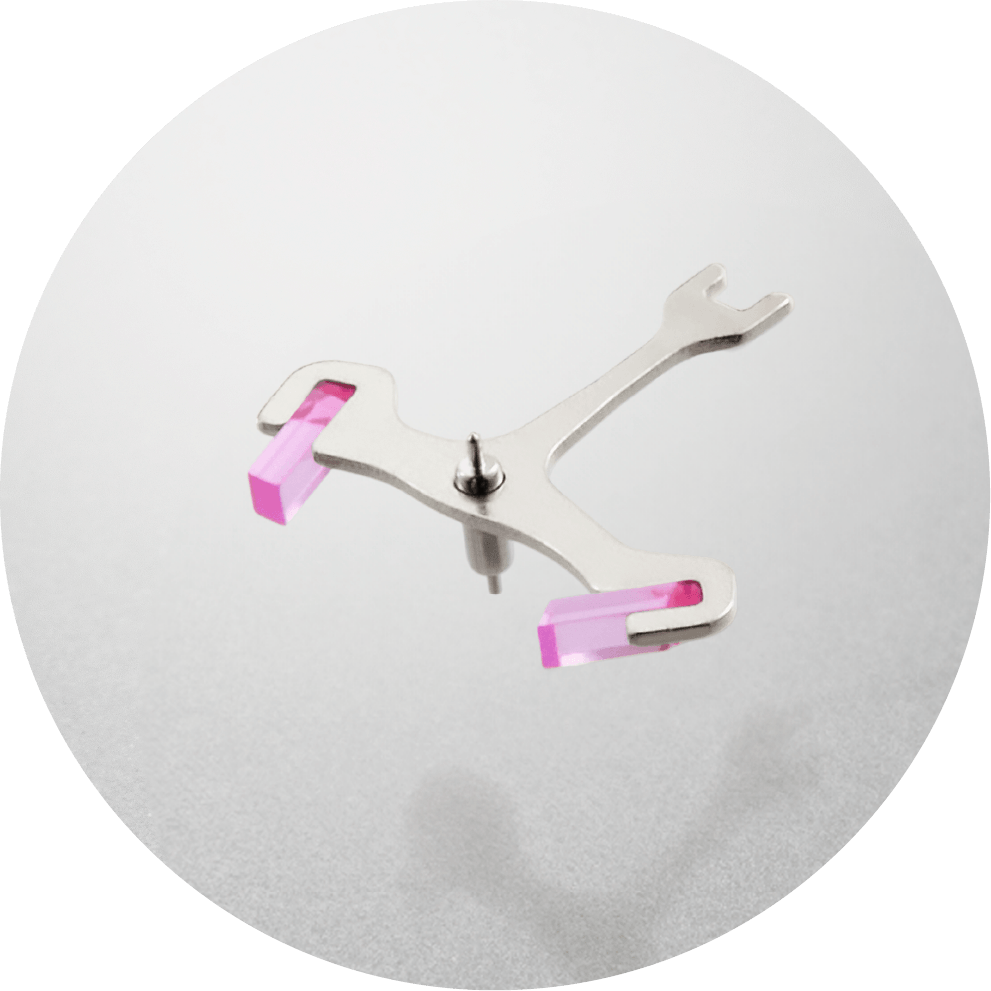

Watches contain gears of different sizes, with

wheels being the bigger ones and pinions the

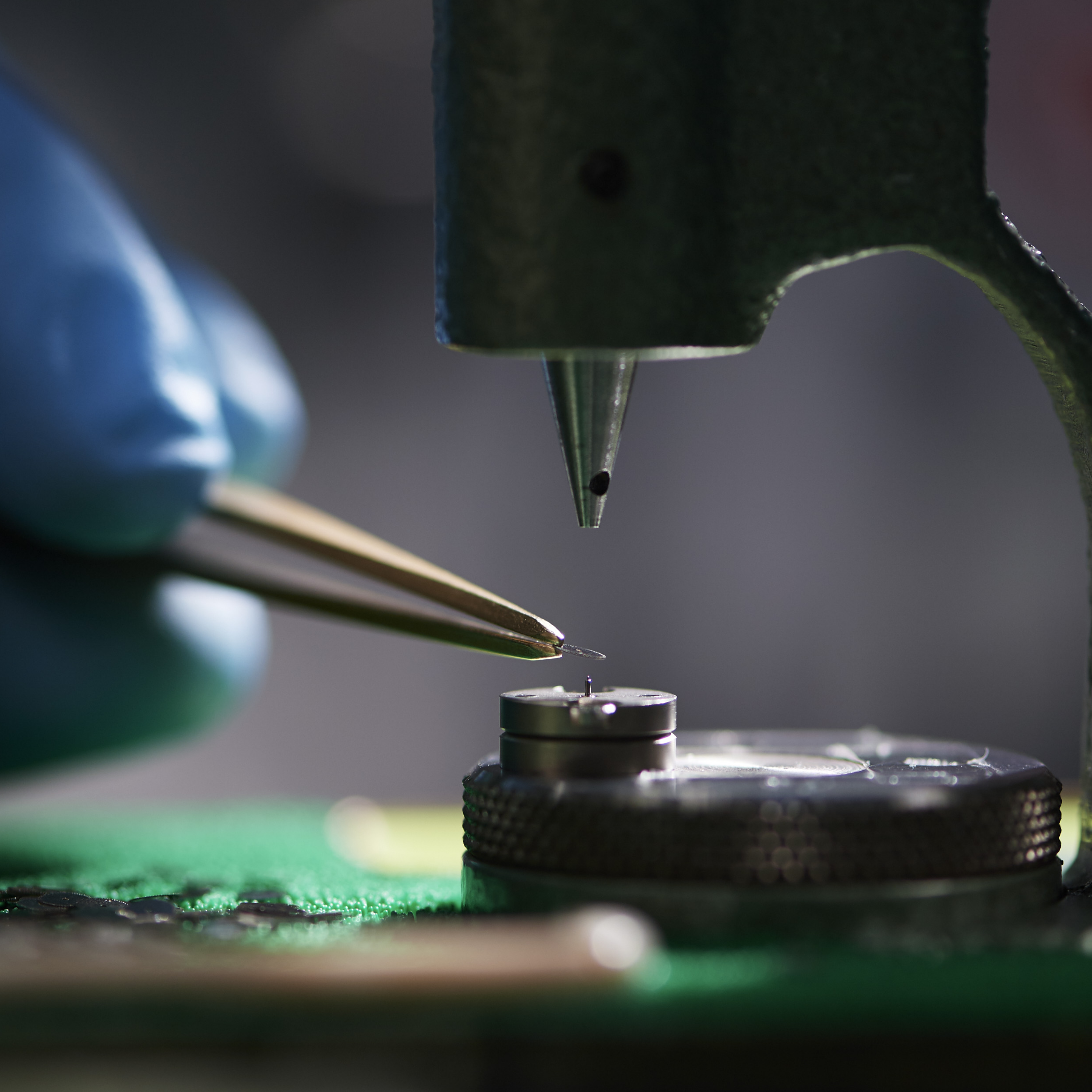

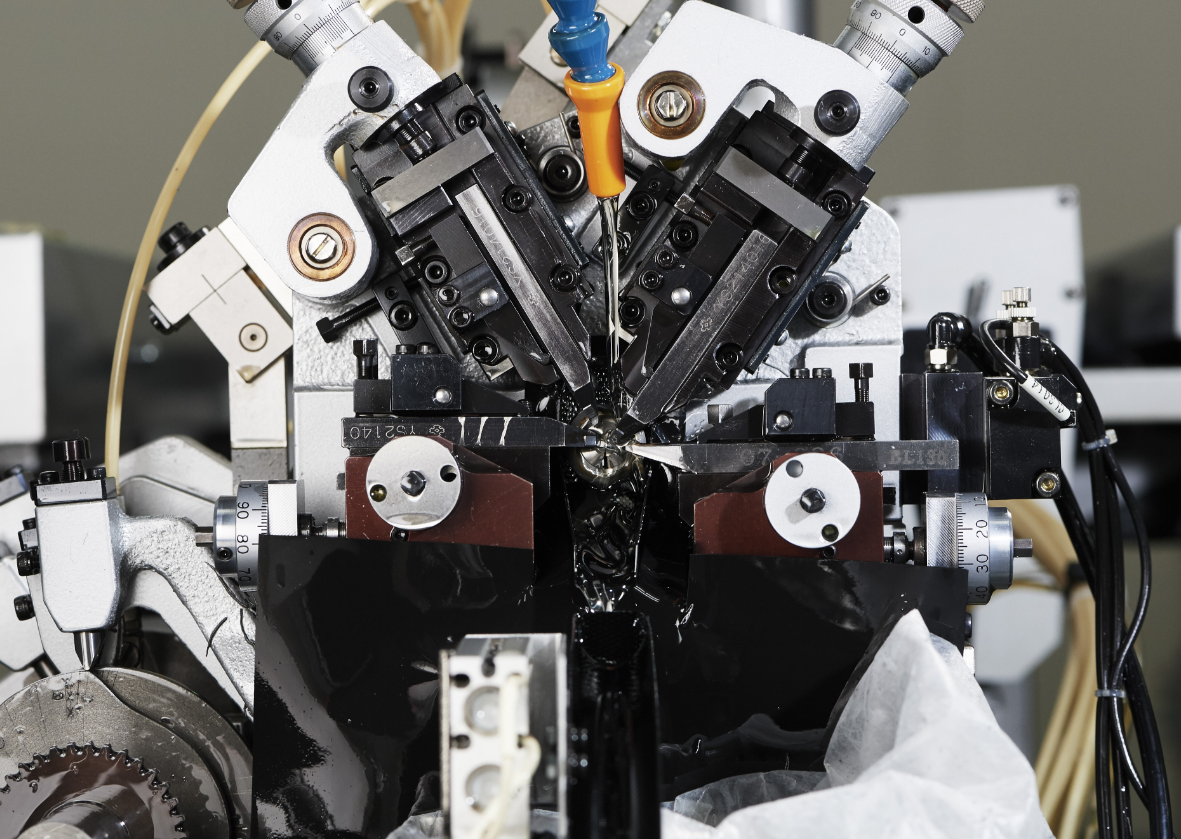

smaller ones. Some of our smallest pinions are

made by grinding a thread-like piece of metal

wire with a diameter of just 1mm on a lathe.

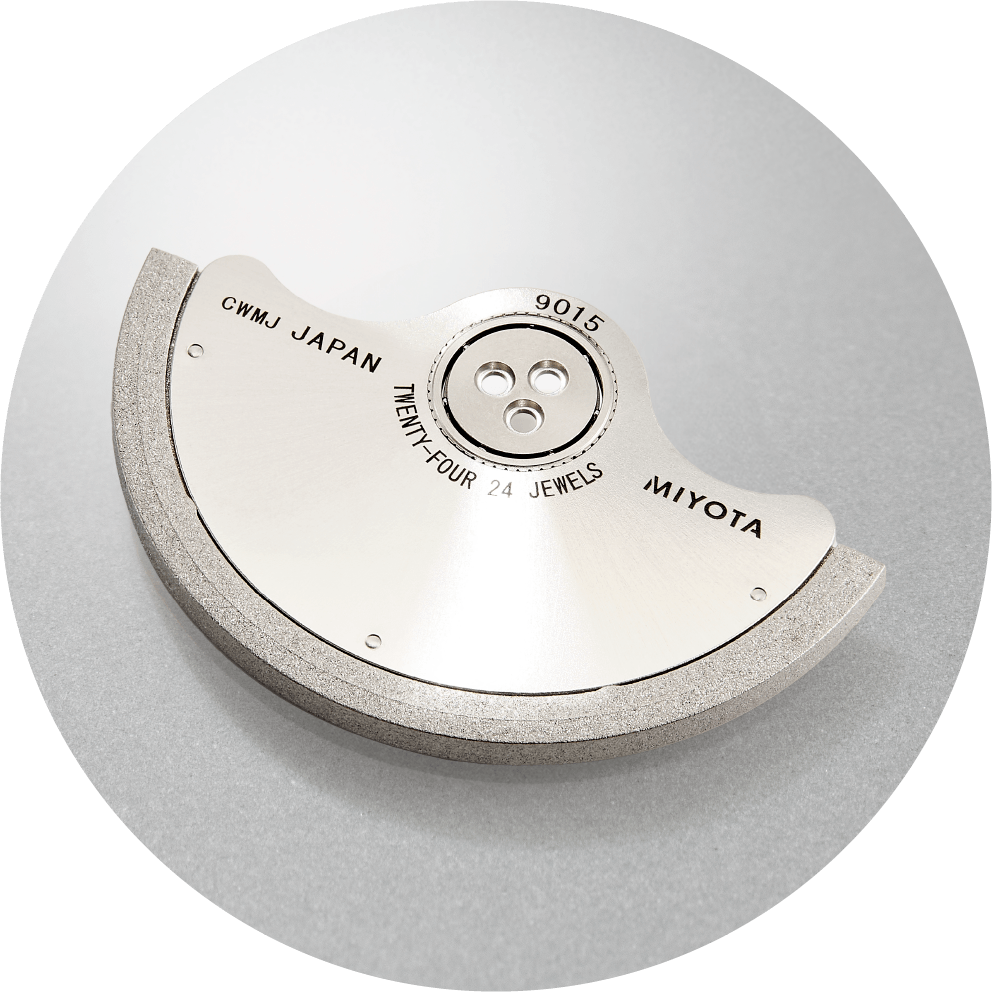

At MIYOTA, we manufacture all our

gears in-house, deploying a range of

machinery, including latest NC lathes,

CAM auto lathes and machine presses,

to do so.

Gears must be micron-level precise. At

MIYOTA, we use cutting tools we developed

in-house because no commercially available

products are able to deliver the high level of

precision we insist on. After all, to make

high-precision parts, you need

high-precision tools.