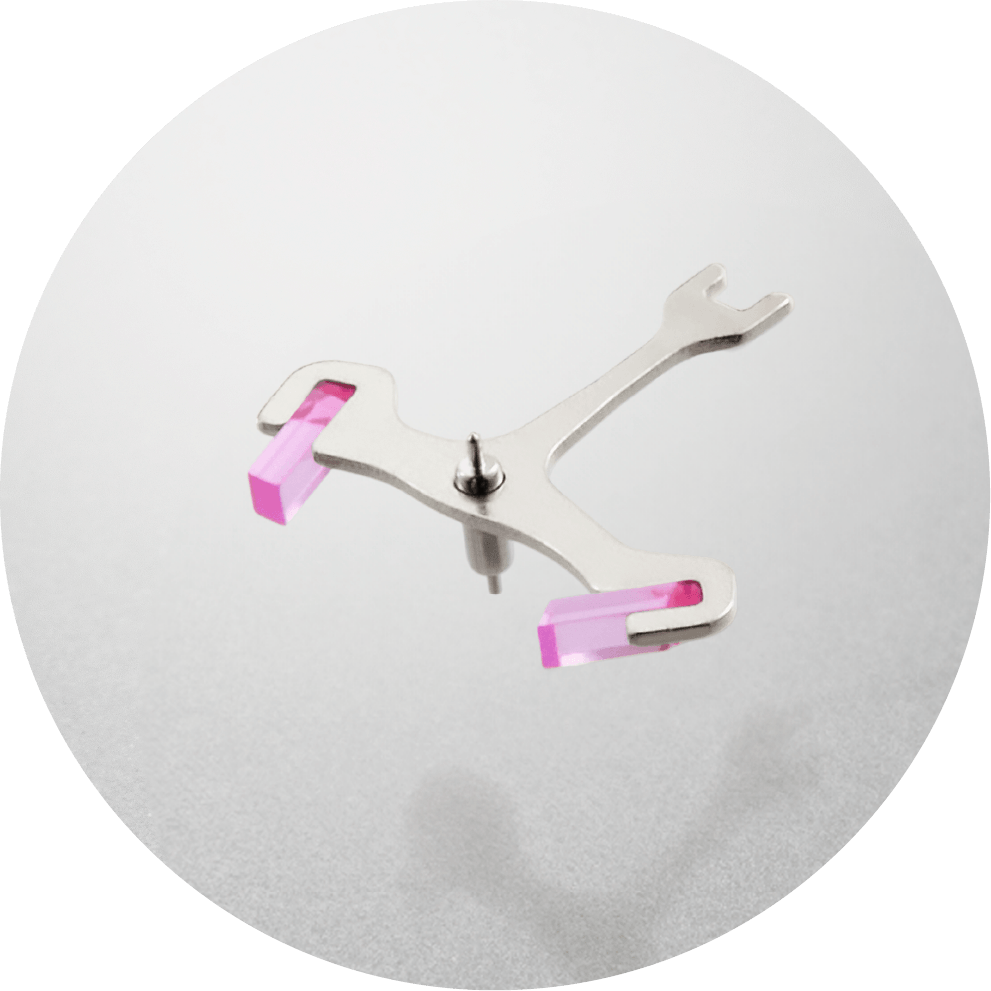

HAIRSPRINGS

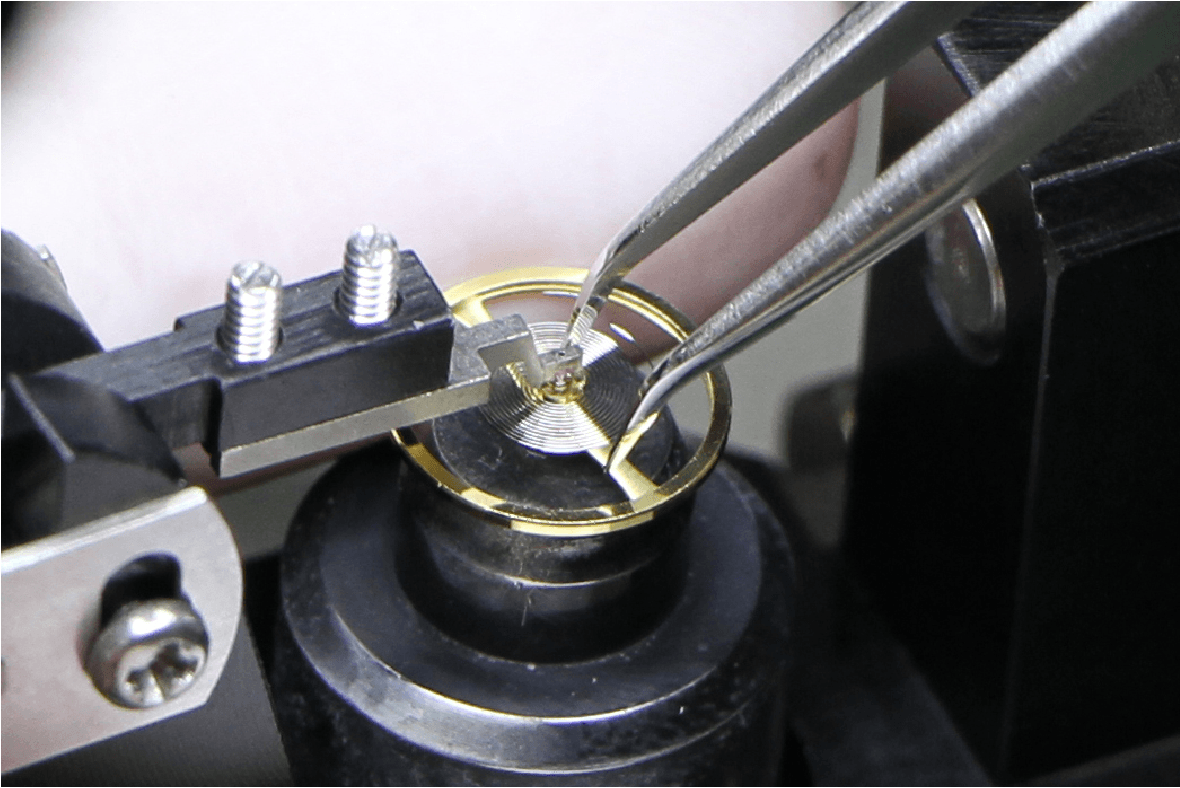

The final step

is done by hand

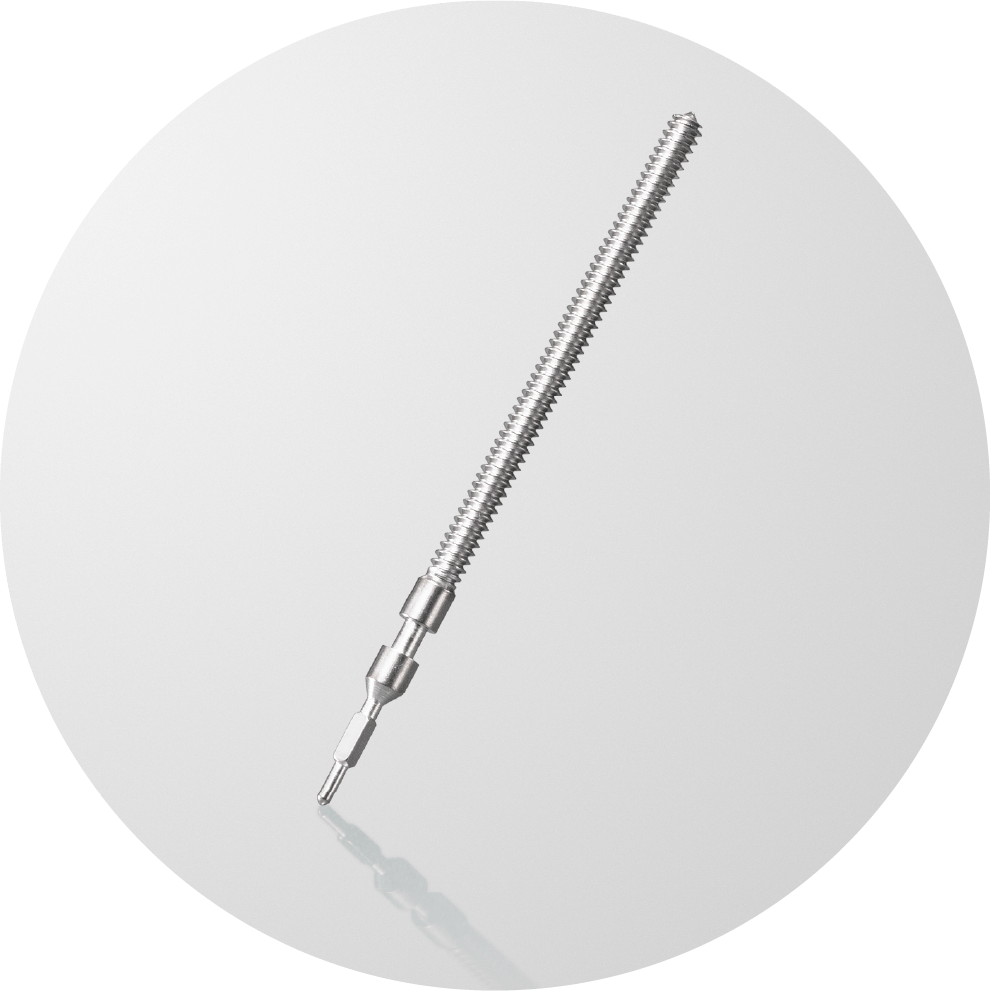

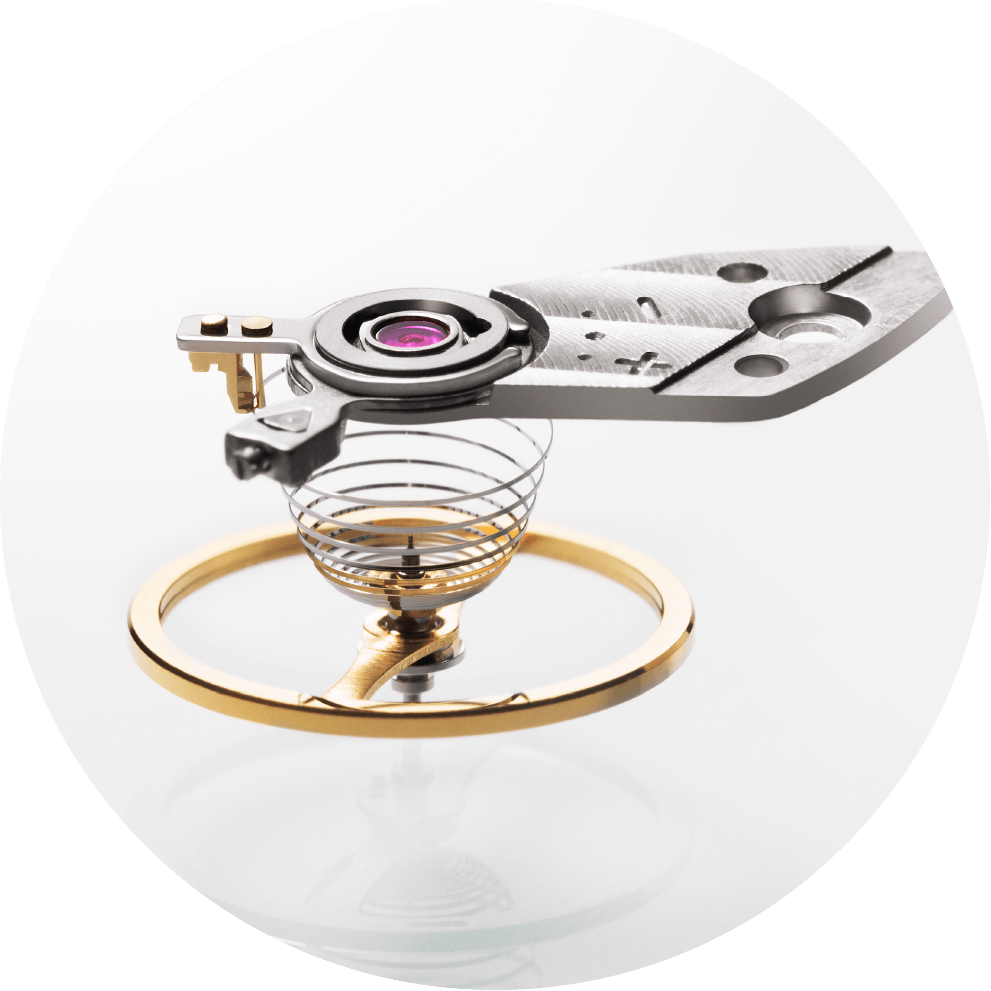

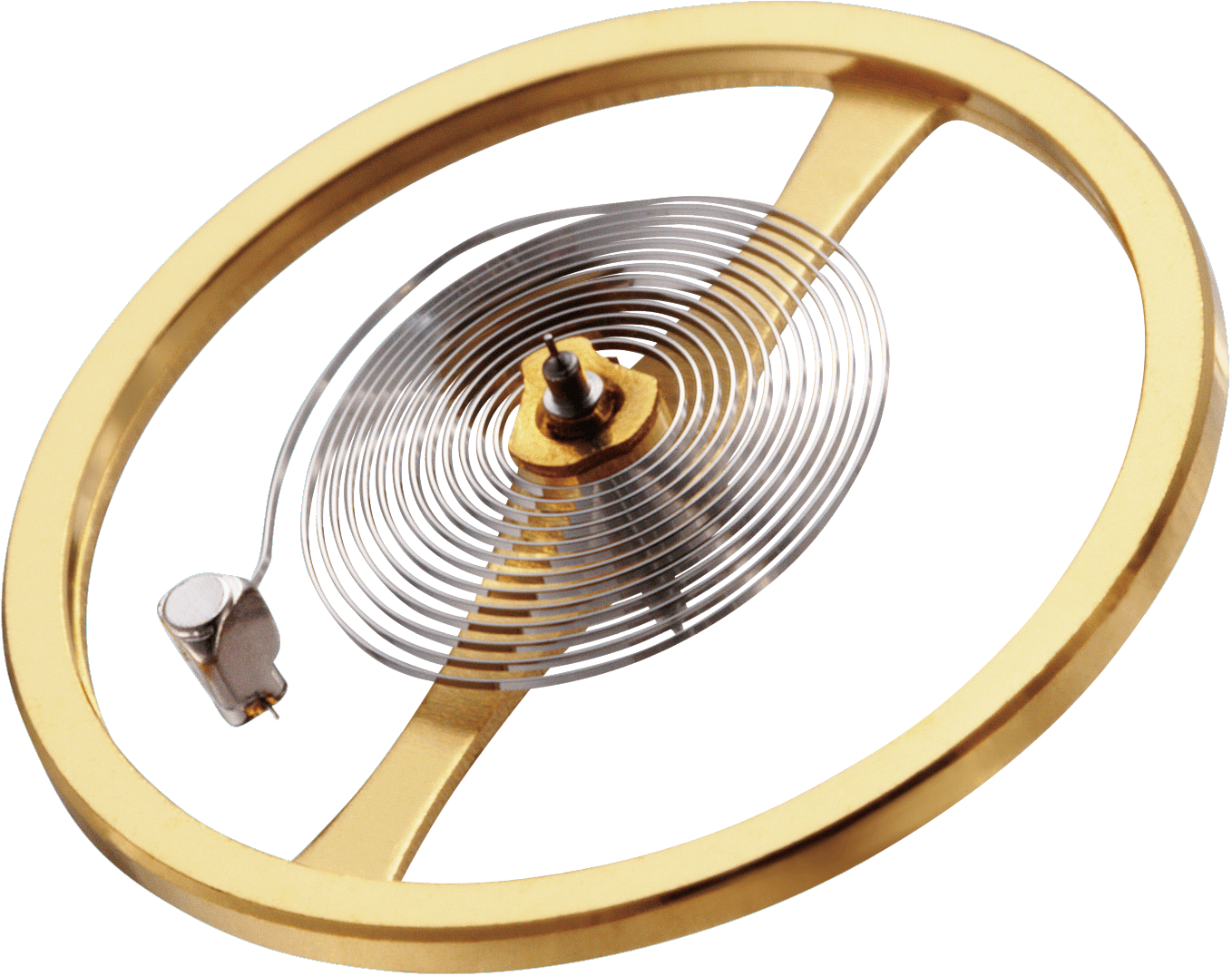

Often described as the beating heart of the mechanical

watch, the hairspring is a spiral spring attached to the

balance wheel. It is the most crucial component when it

comes to determining the accuracy of a watch.

0.1μm =

1/10,000mm

The hairspring is made by drawing, rolling and flattening metal

wire. Since timekeeping accuracy depends upon achieving

precisely the right thickness, temperature and humidity must

be kept at constant levels throughout the manufacturing

process to keep tolerances

under 0.1 micron. The process is so

technically challenging that only a handful of watchmakers

worldwide can make their own hairsprings.

At MIYOTA, we spend a great deal of time and care making our

hairsprings, all under the most rigorous quality-management regime.

Only a select group of highly experienced

specialist craftspeople are allowed to handle the

final step of the process, the shaping of the

terminal curve. Combining human skill and

machine capabilities like this is what enables us

to produce hairsprings of such high precision

and quality levels.