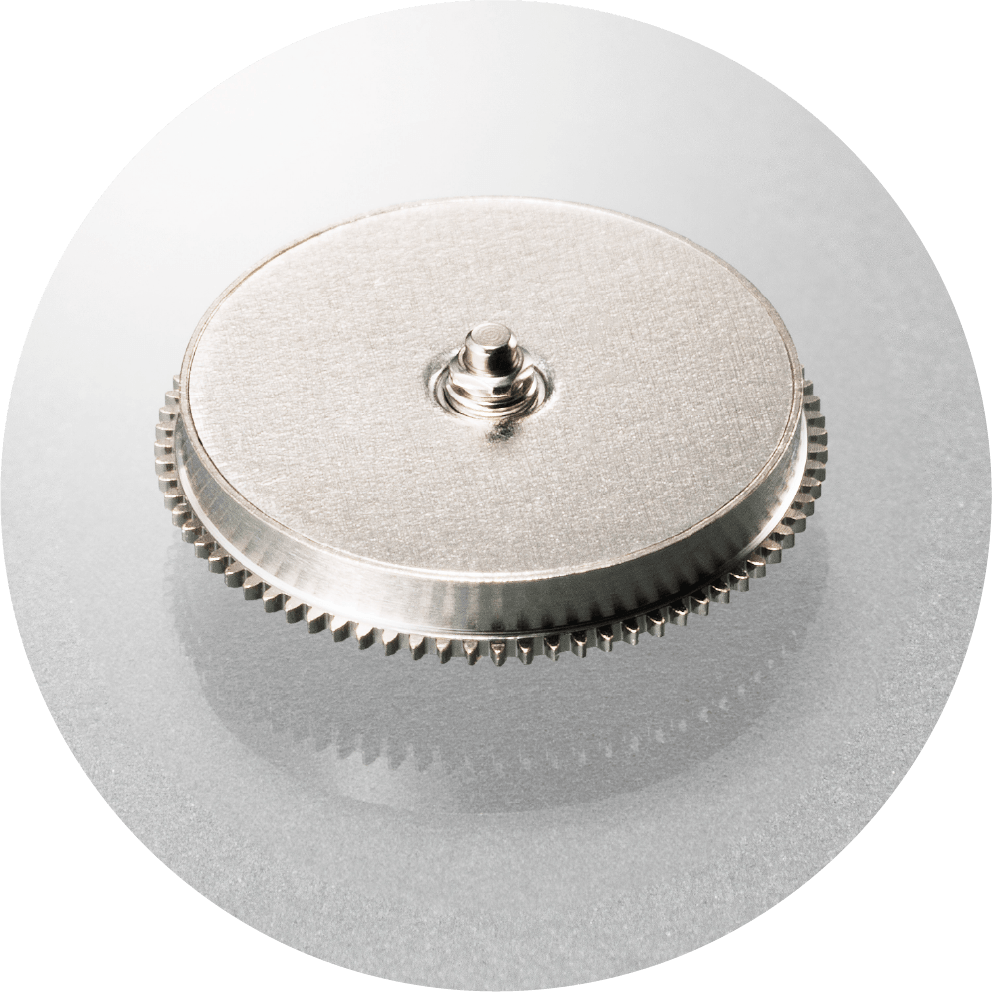

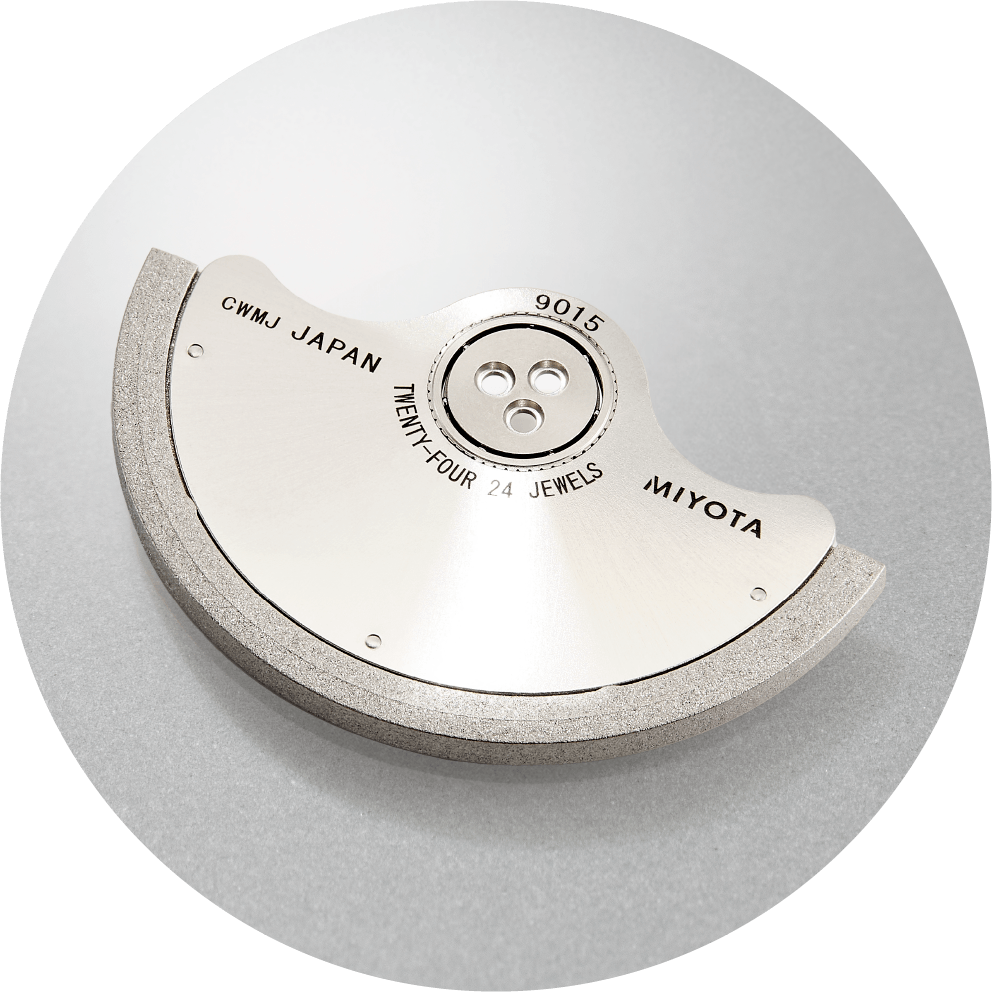

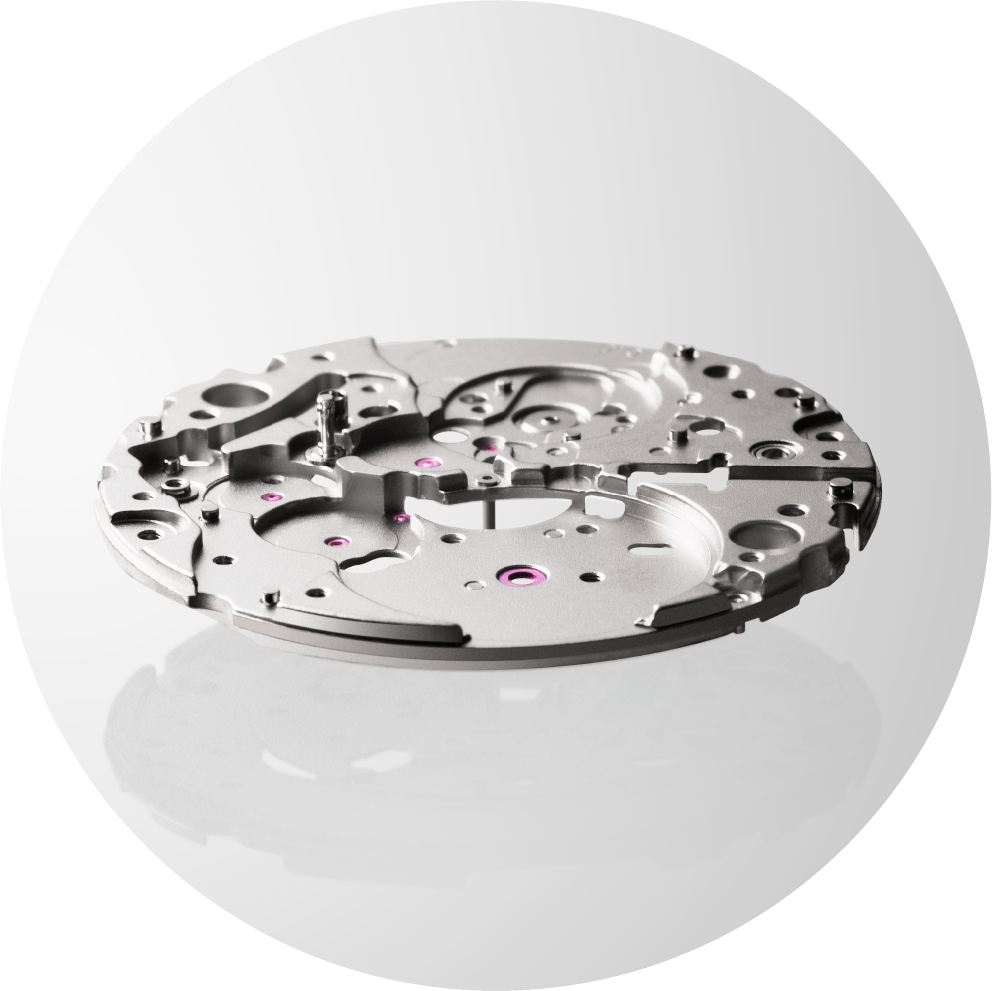

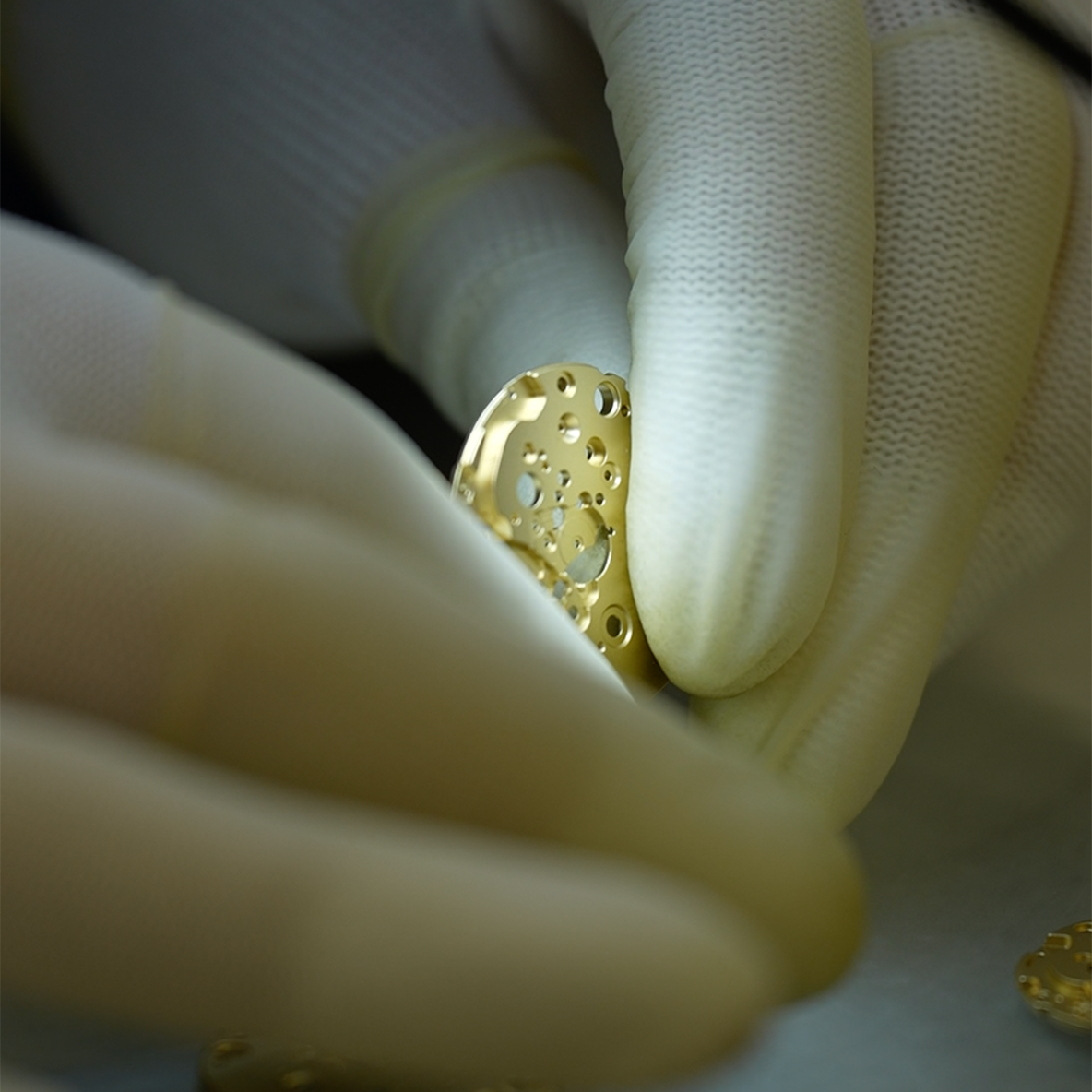

MAIN PLATES

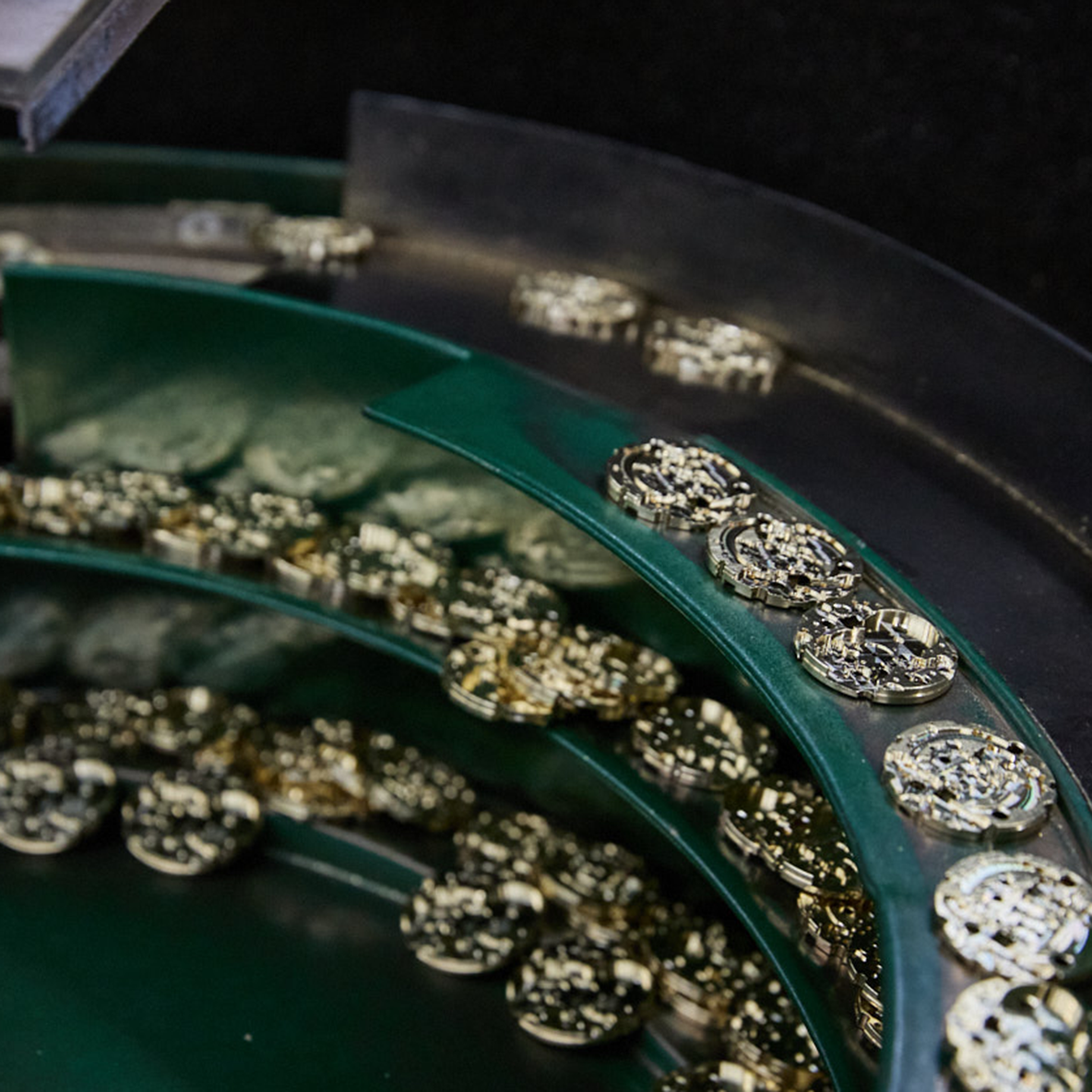

More than 50 processes go into

making a single main plate

The main plate is the base to which all the different

components of a movement are attached. A large

number of processes, from pressing and washing,

go into the manufacturing of main plates.

The main plate of the MIYOTA 82 Series

mechanical movement is a good example.

It requires over 50 separate processes.

(Some other main plates require as many as 70!)

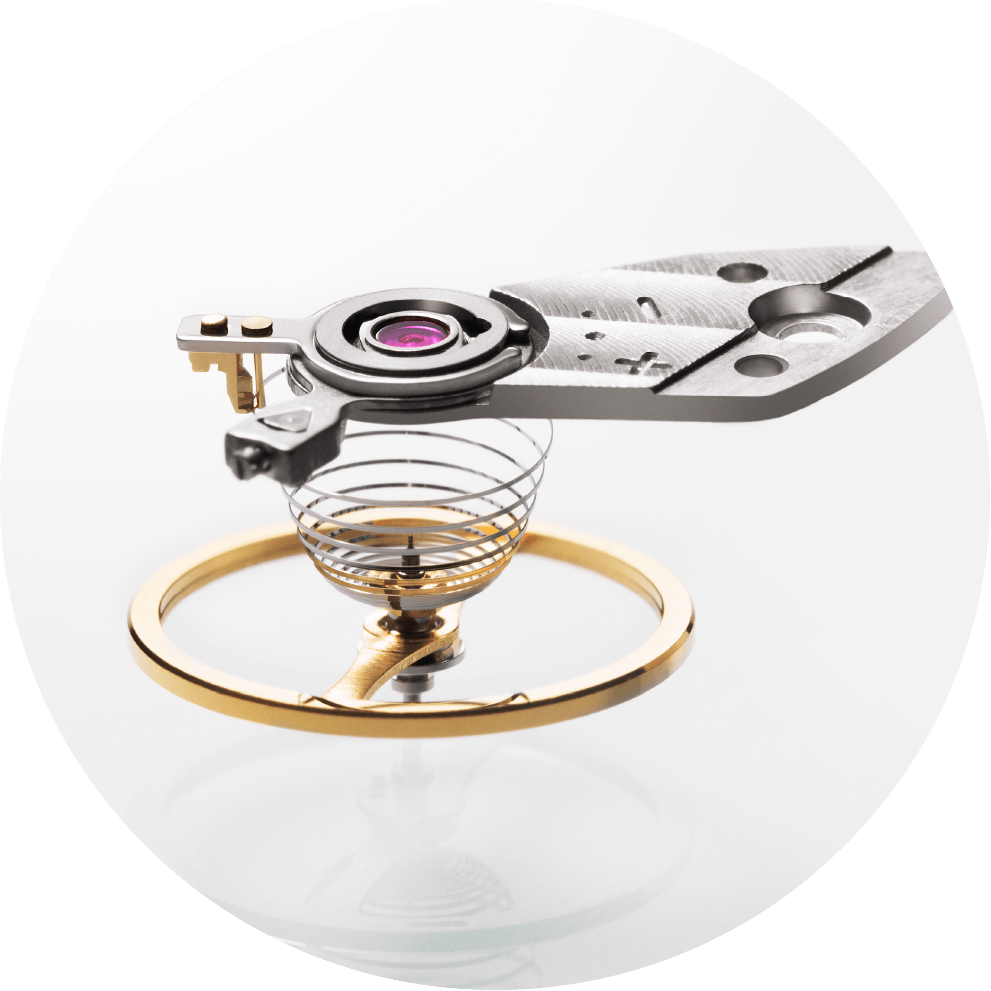

As the framework that holds together all the other

high-precision parts, the main plate itself need to be

highly precise. That is why we make both the dies for

pressing and the tools for milling our main plates in-house.

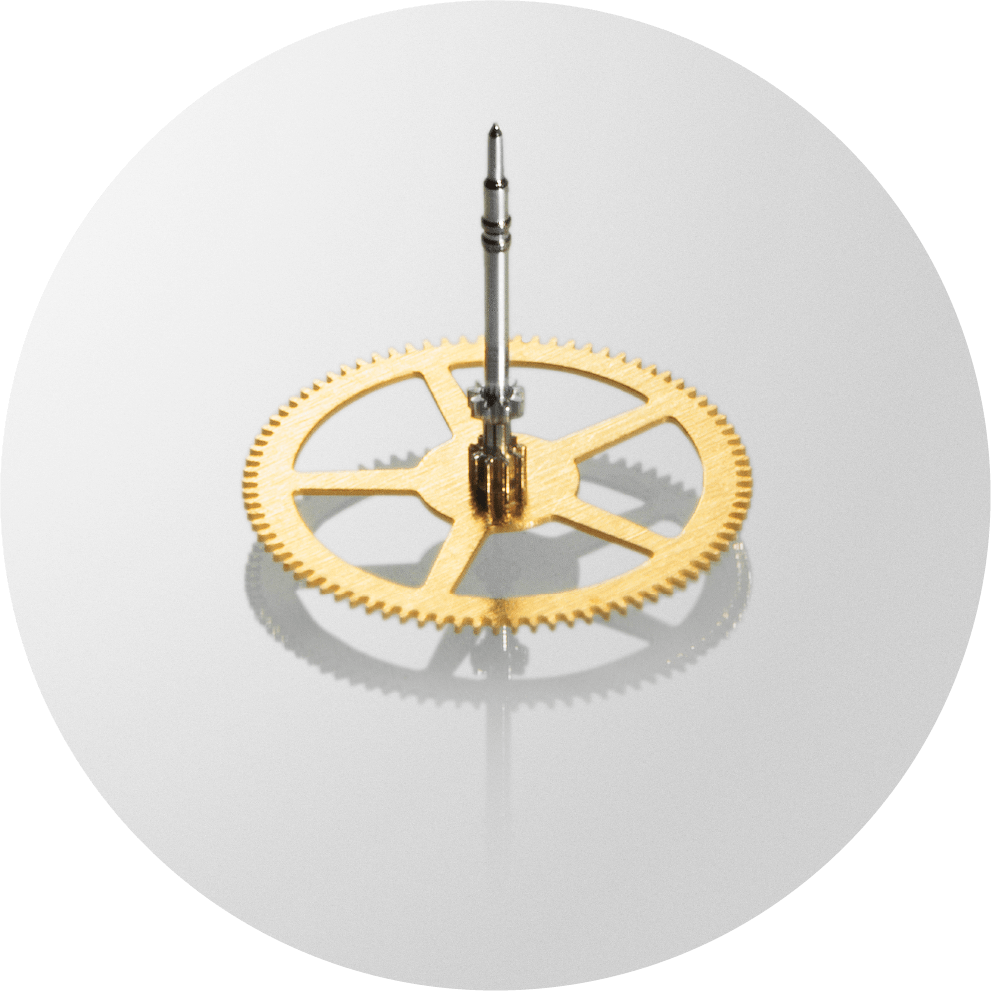

Like a master chef presenting

a signature dish with exquisite plating,

creating amovement that keeps

accurate time requires arranging

multiple delicate and precise parts in

just the right position. That is why

zero-defect quality is an absolute must.