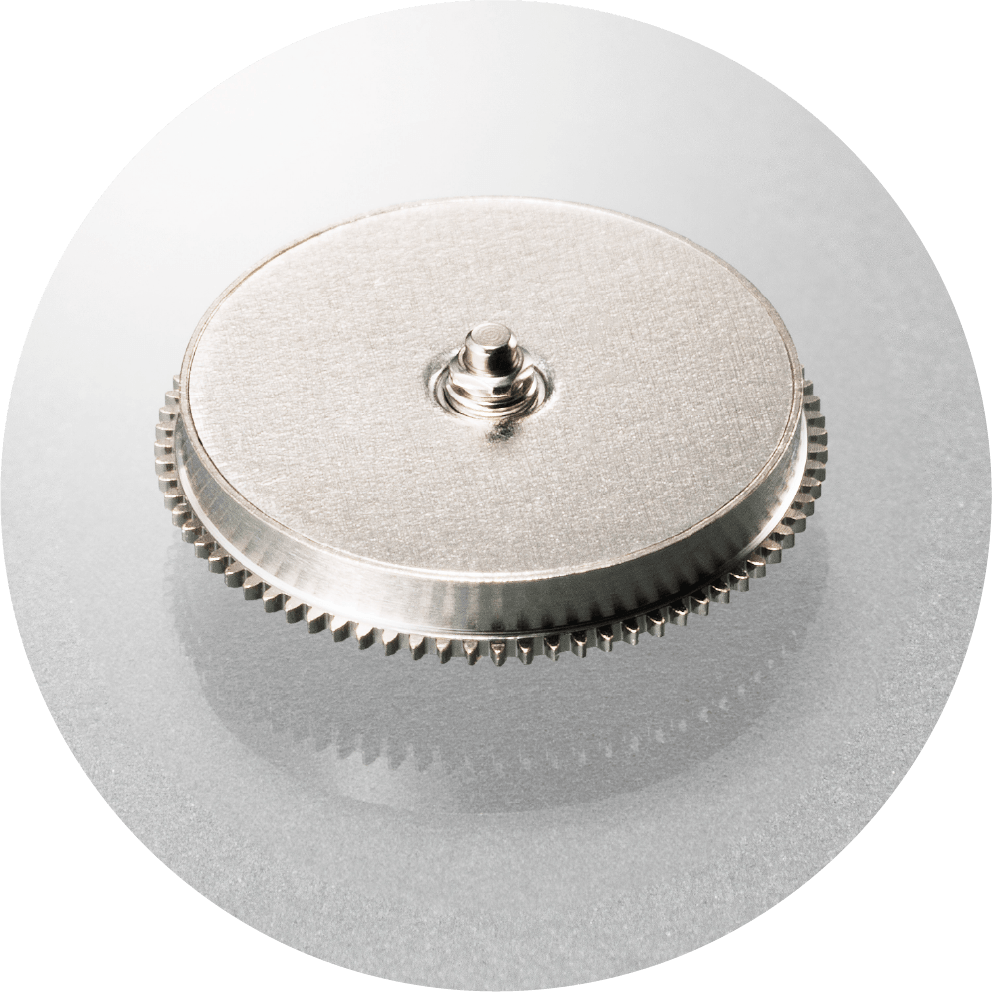

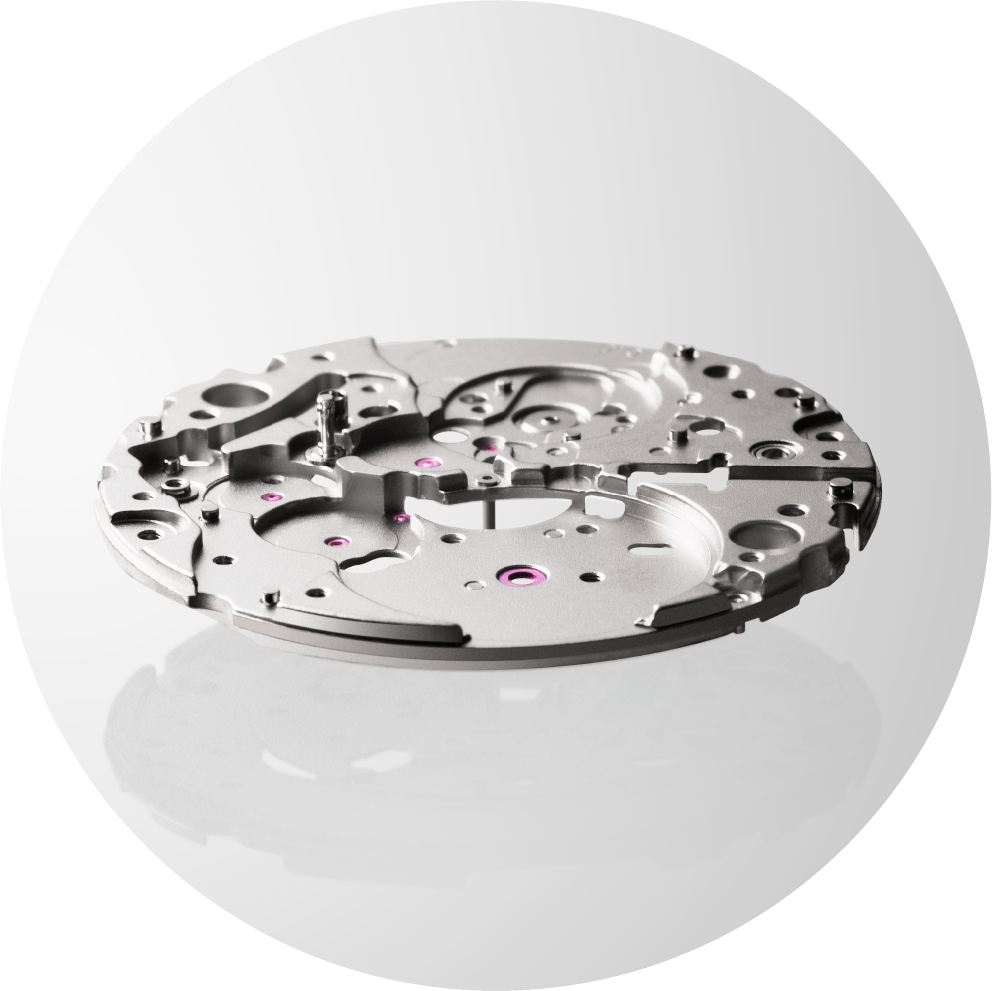

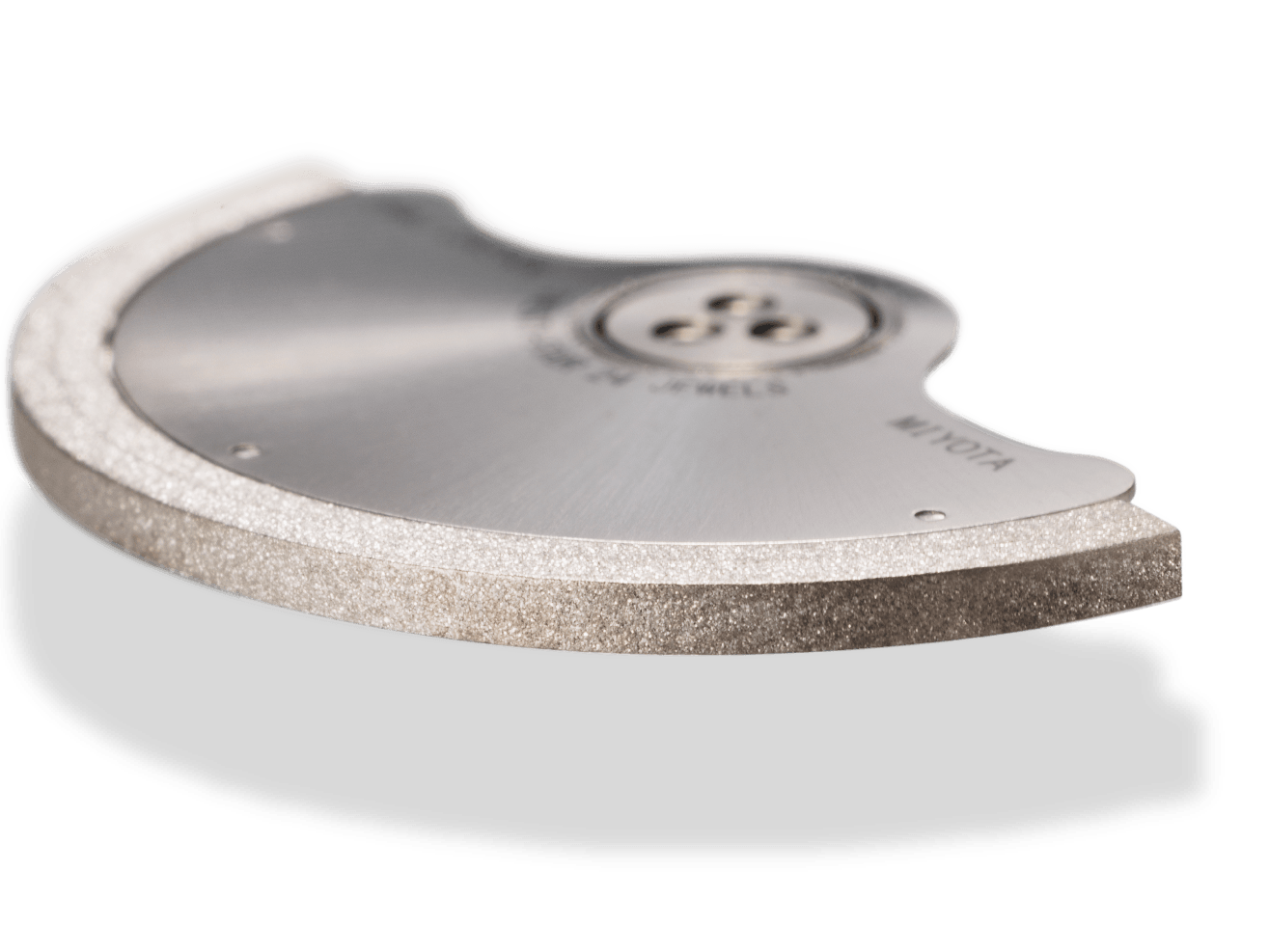

OSCILLATING WEIGHTS

Getting a hard-to-process metal

to swing our way

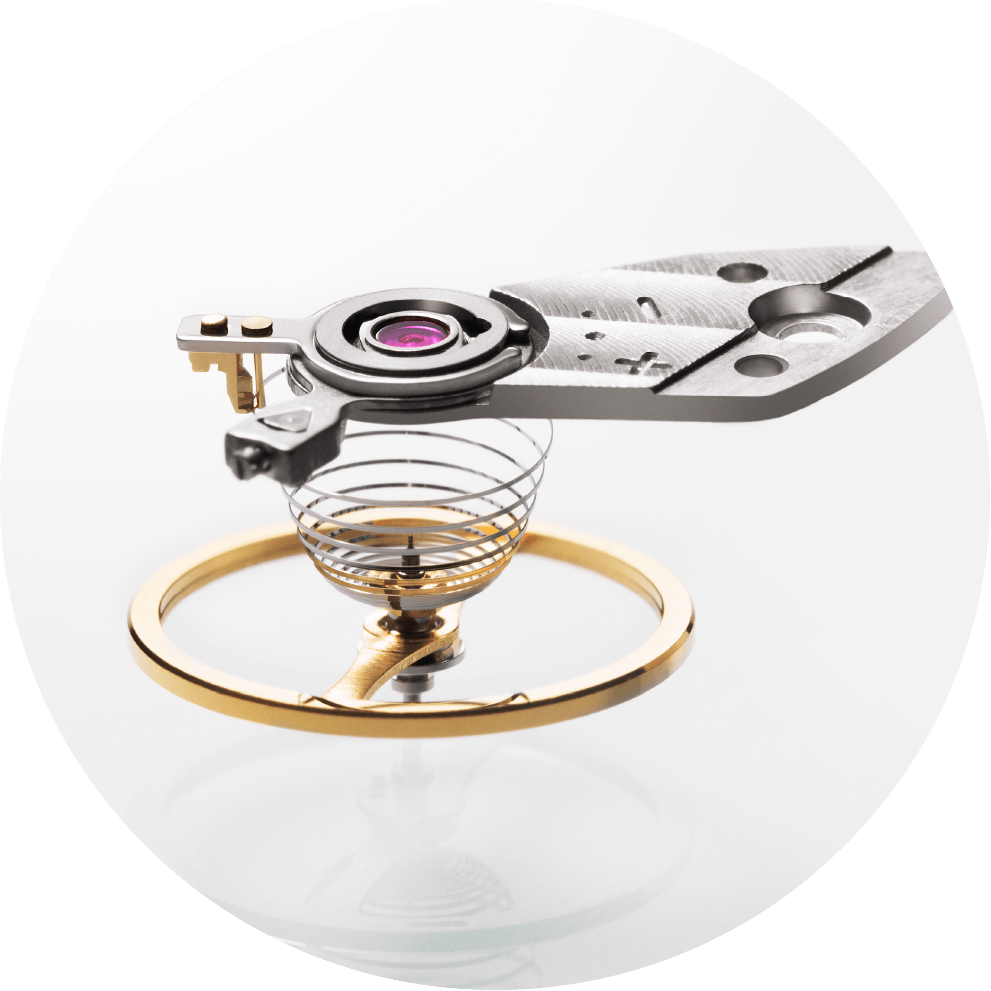

The oscillating weight, which swings with every motion of the wrist,

is a weight which winds the mainspring.

Stability and precision are essential to minimize any deviations

during rotation of the oscillating weight and to make sure

that it swings with the requisite smoothness and consistency.

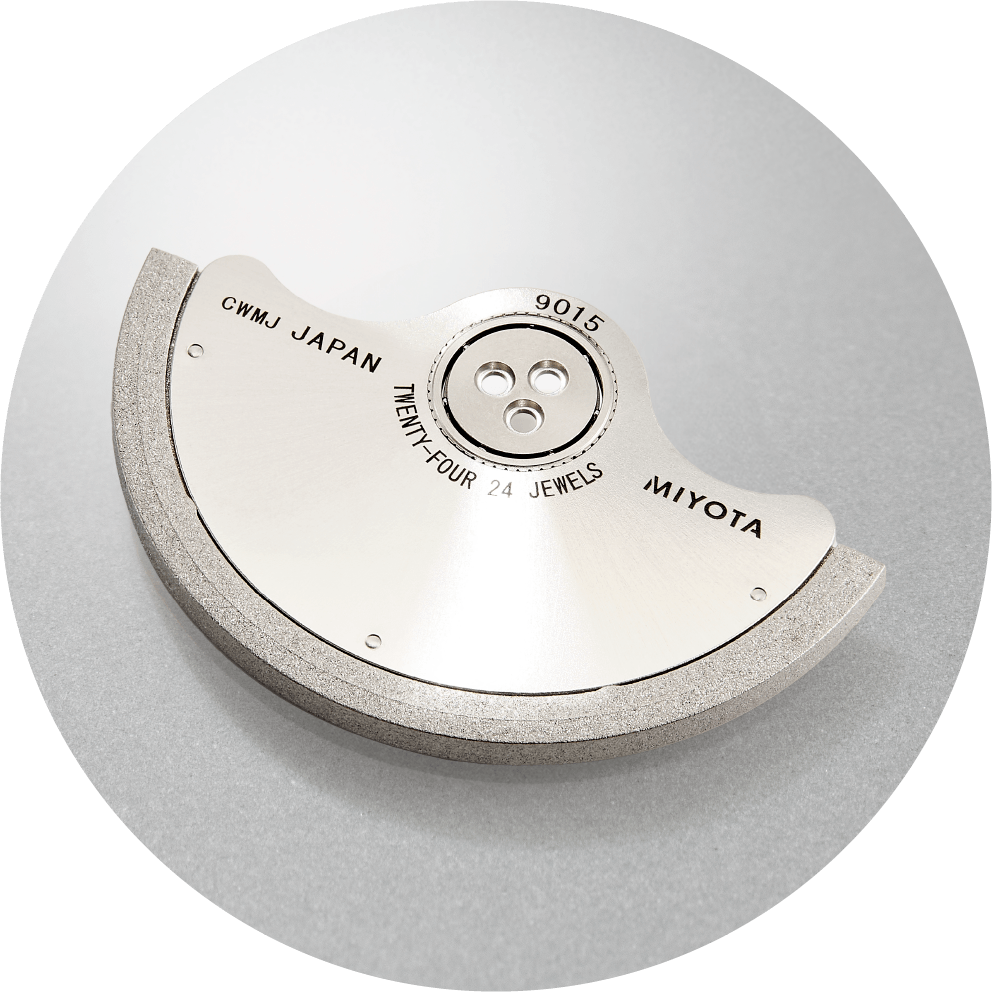

At MIYOTA, we use tungsten for our oscillating weights.

Because tungsten is a metal with a high specific gravity,

it winds the mainspring with enhanced efficiency.

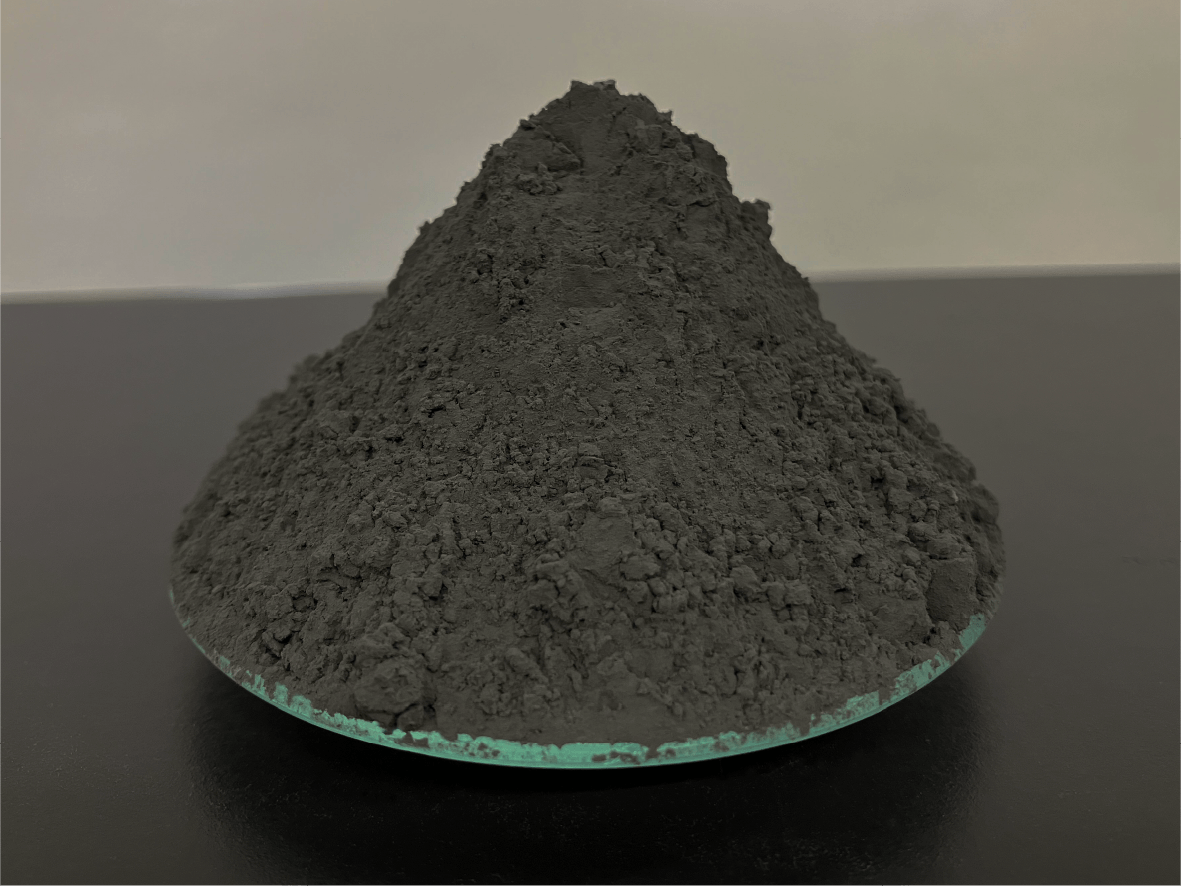

Since, however, tungsten is also extremely hard and dense,

it is by no means an easy metal to process.

That is why we use powder injection molding technology

to achieve the perfect shape.

The finished oscillating weight

is precise down to the last detail despite

the difficulties inherent in the material.

We can pull this off

because we make our own components in-house.

(Powder injection molding technology also makes

the most effective use of the raw materials with minimum waste.)

Creating finished oscillating weights that are safely

within the demanding tolerances we set ourselves is challenging

because we have to anticipate any changes in size

that will occur during the forming and firing processes.

It is because we do everything in-house—from detailed design

and advanced processing through to meticulous final assembly—

that MIYOTA can successfully meet and overcome this challenge.