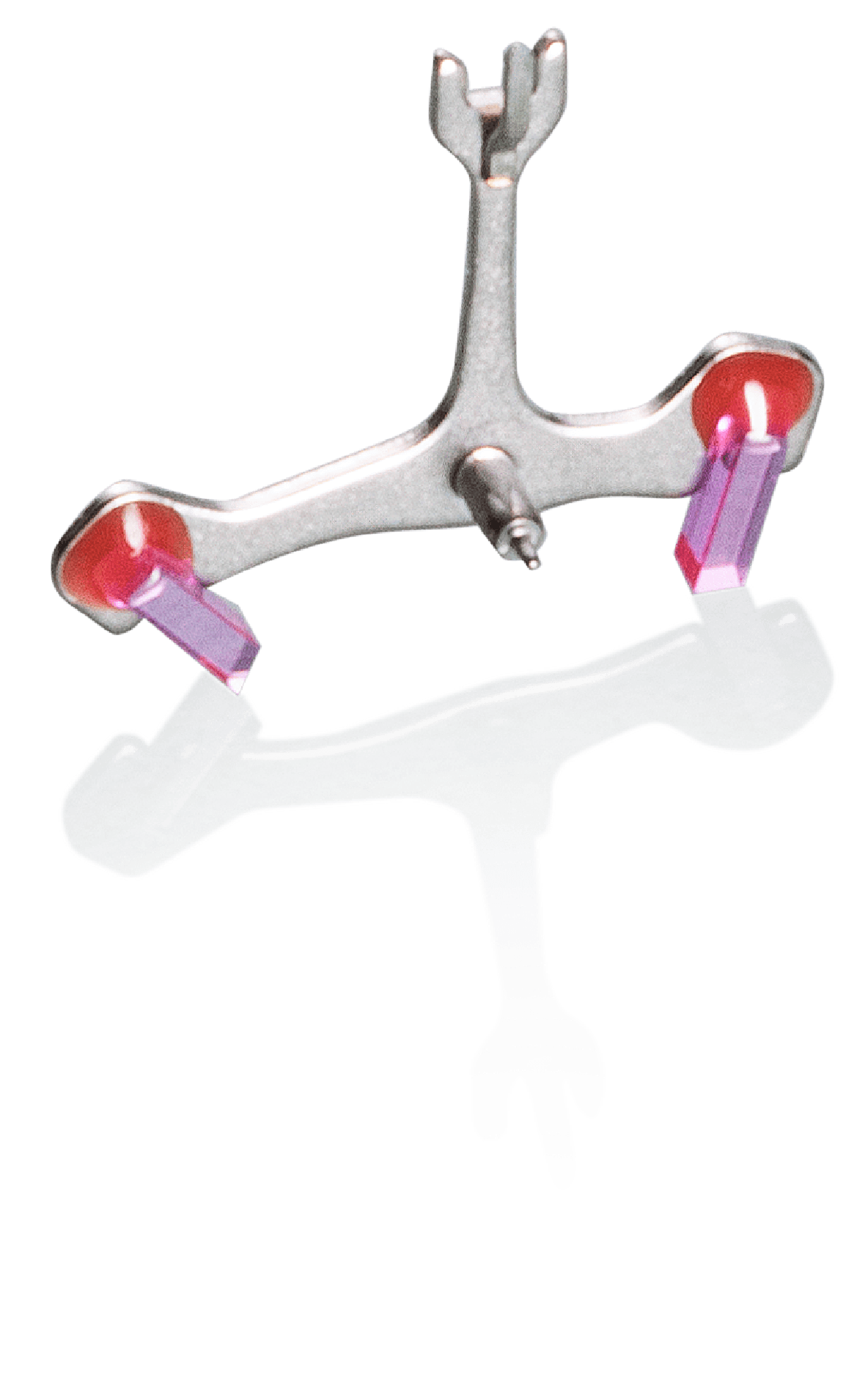

PALLET FORKS

Five components, each smaller

than a grain of rice

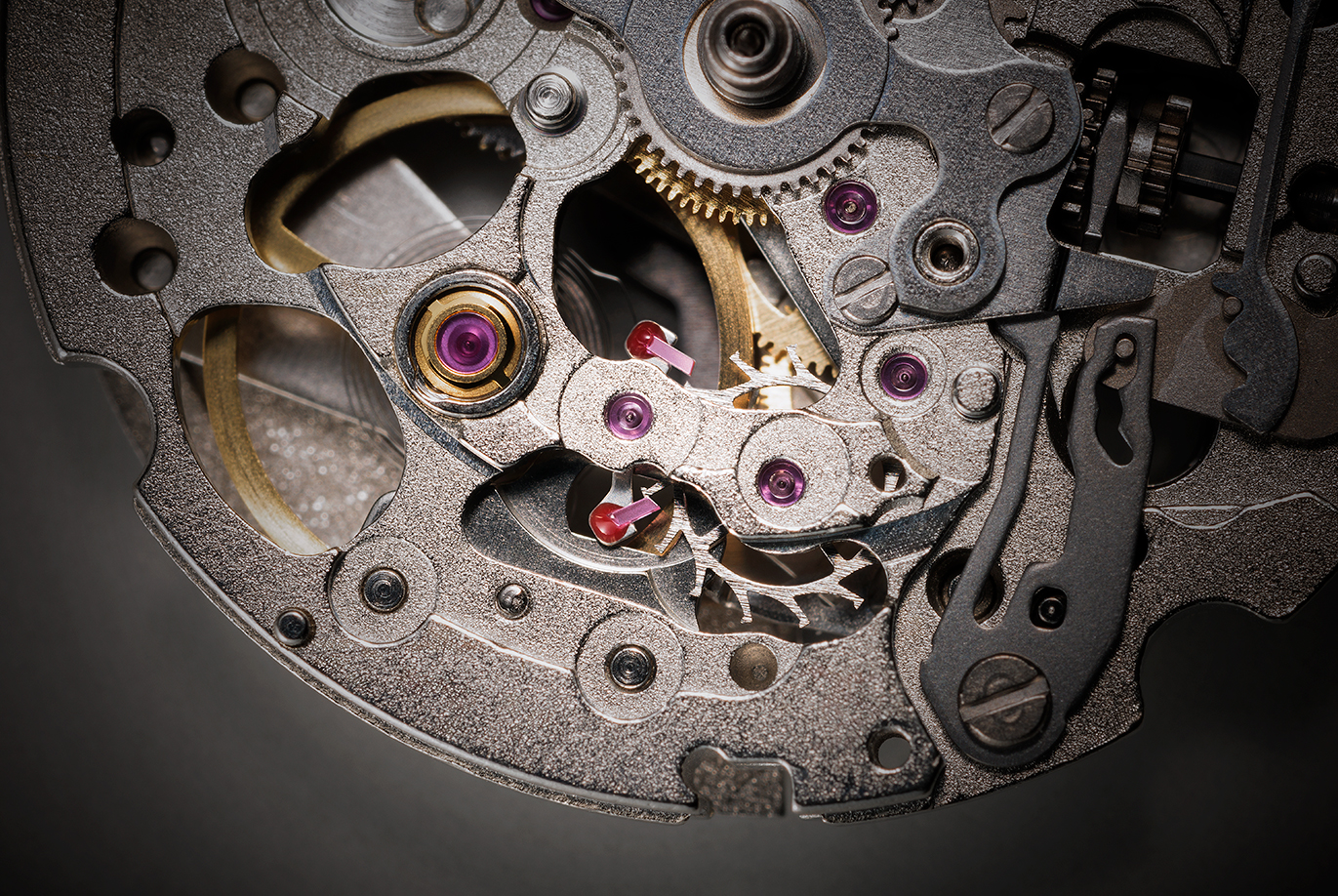

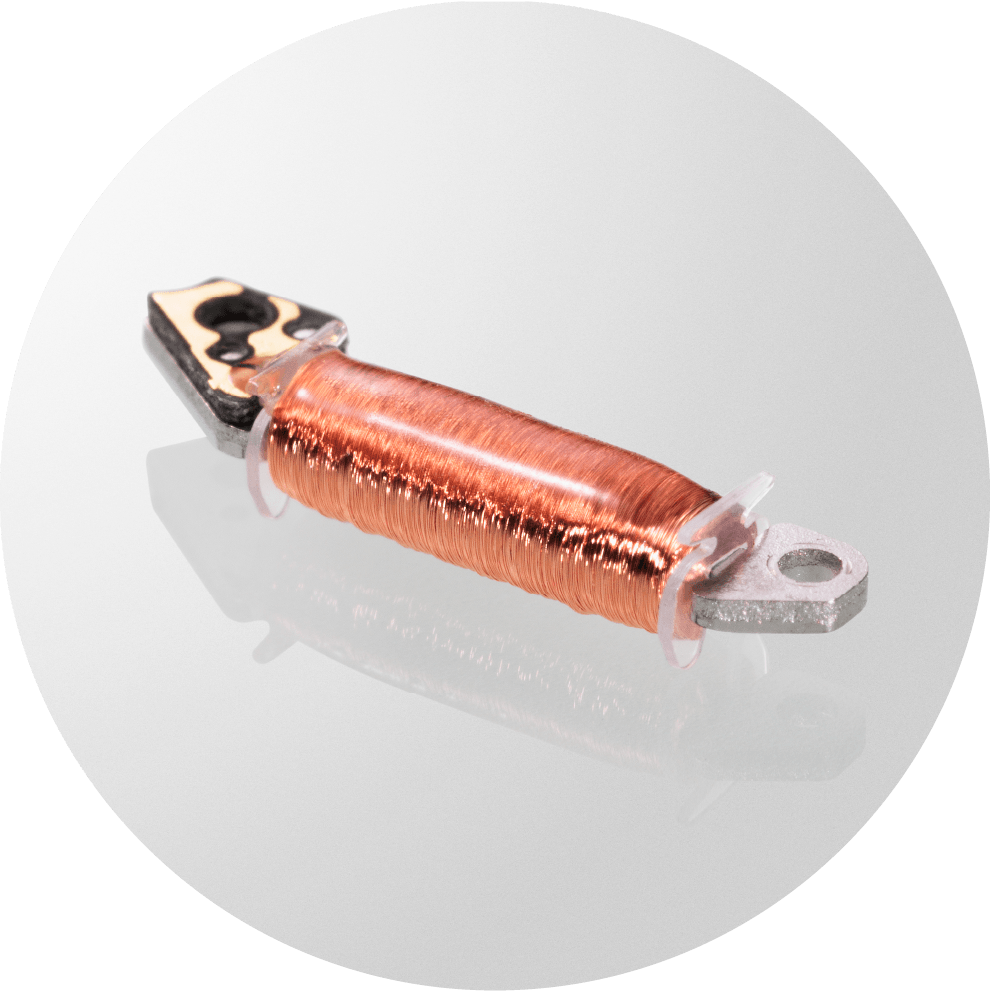

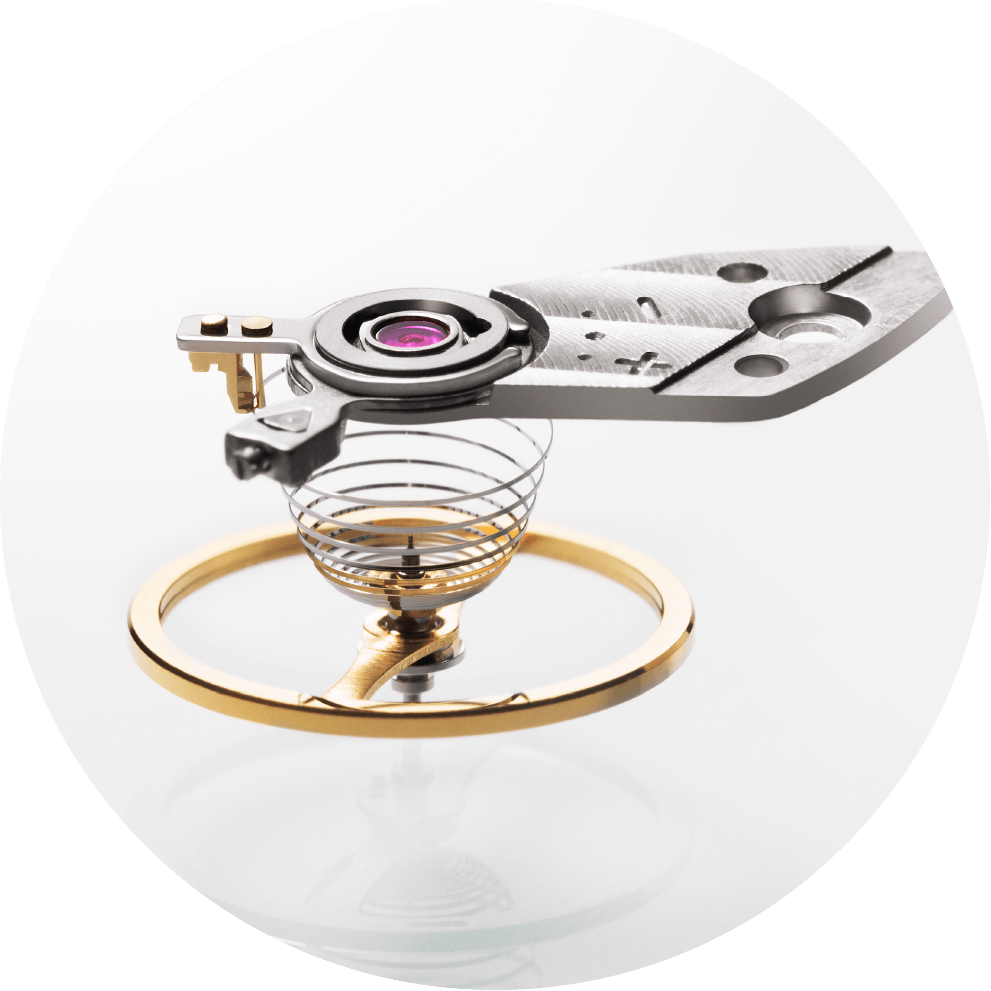

The anchor-shaped pallet fork is one of the components

that make up the escapement.

(The escapement’s role is to control the advancement of the hands

in a mechanical watch.)

The ticking sound that mechanical watches make is

in fact the sound of the pallet fork’s jewels

catching on the escape wheel.

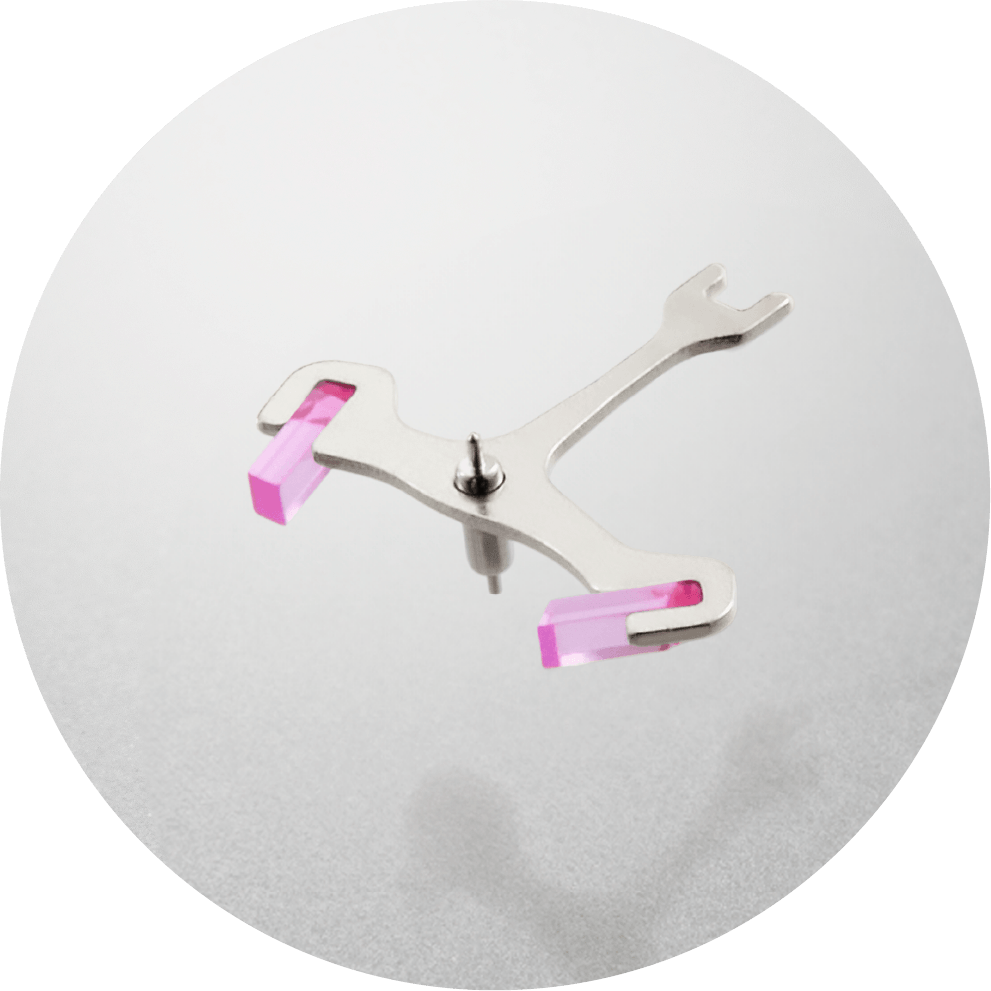

Not only is the pallet fork an extremely complex shape;

it is actually made by joining five separate components each of which

is smaller than a single grain of rice!

Using techniques ranging from plastic deformation processing

(pressing the workpiece into a die to shape it) and press-fitting

(pushing parts together so the joint is held together by friction) to welding,

we automatically assemble the ultra-small components

into pallet forks using a high-precision process with no latitude for deviation.

In this way, precision of assembly is every bit as important as the precision

of the individual components for MIYOTA.

For example, when the jewels are fitted to the pallet fork,

they have to be placed in exactly the right position to ensure

that they mesh properly with the escape wheel.

By taking care to fit the jewels with absolute correctness

when we assemble our pallet forks,

MIYOTA builds quality movements of sustained stability and reliability.