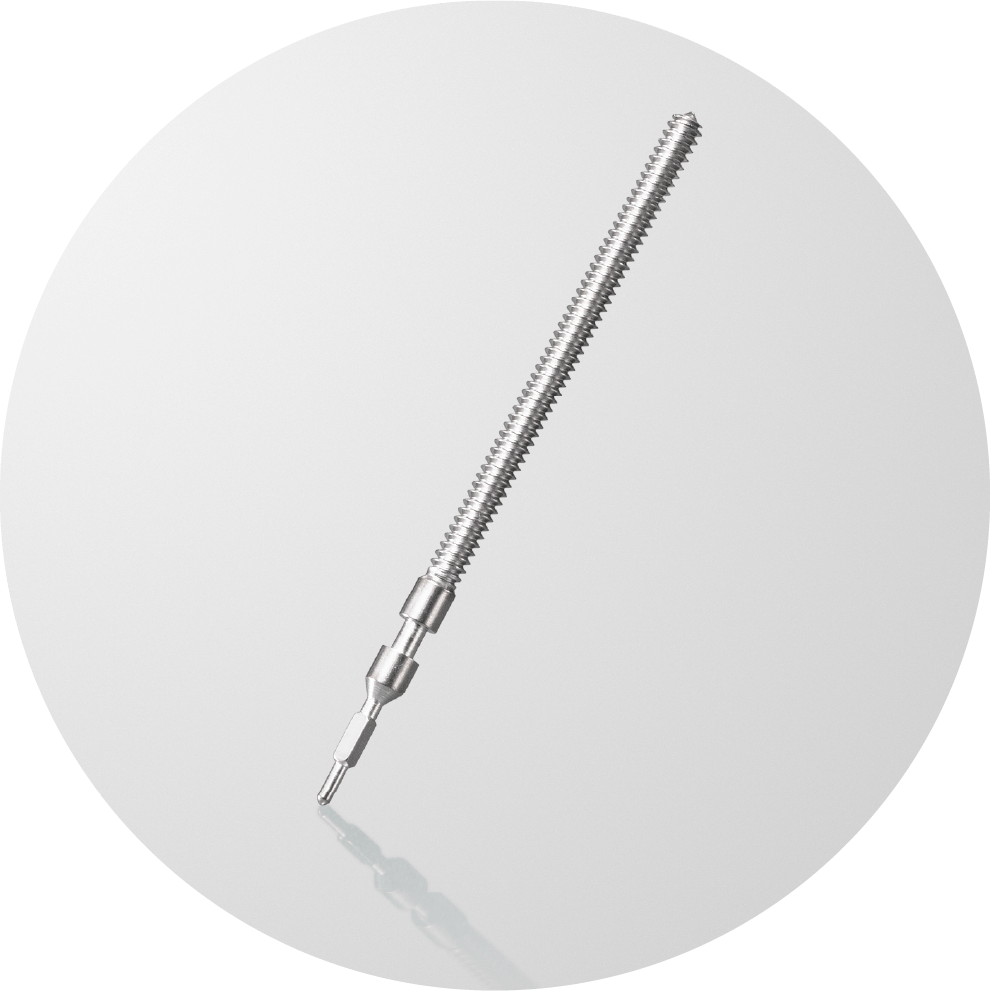

SCREWS

Ease of repair is one

aspect of quality

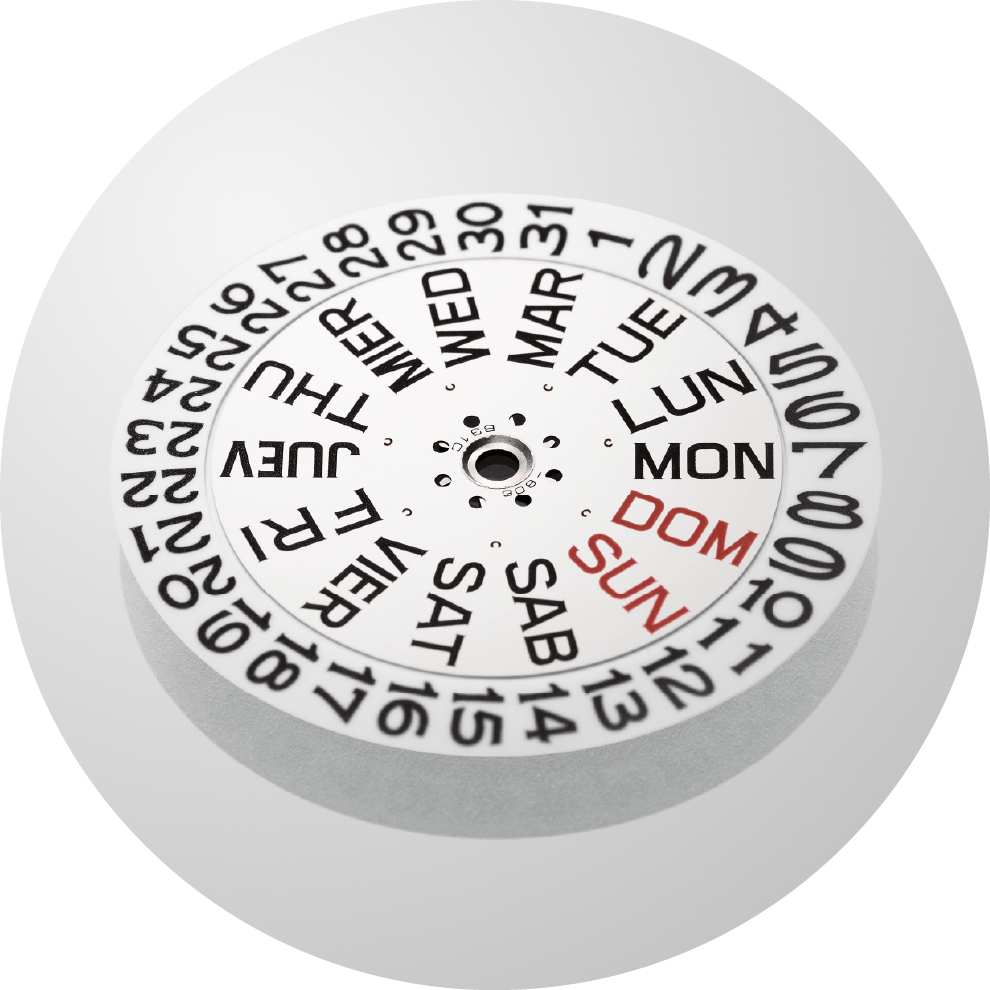

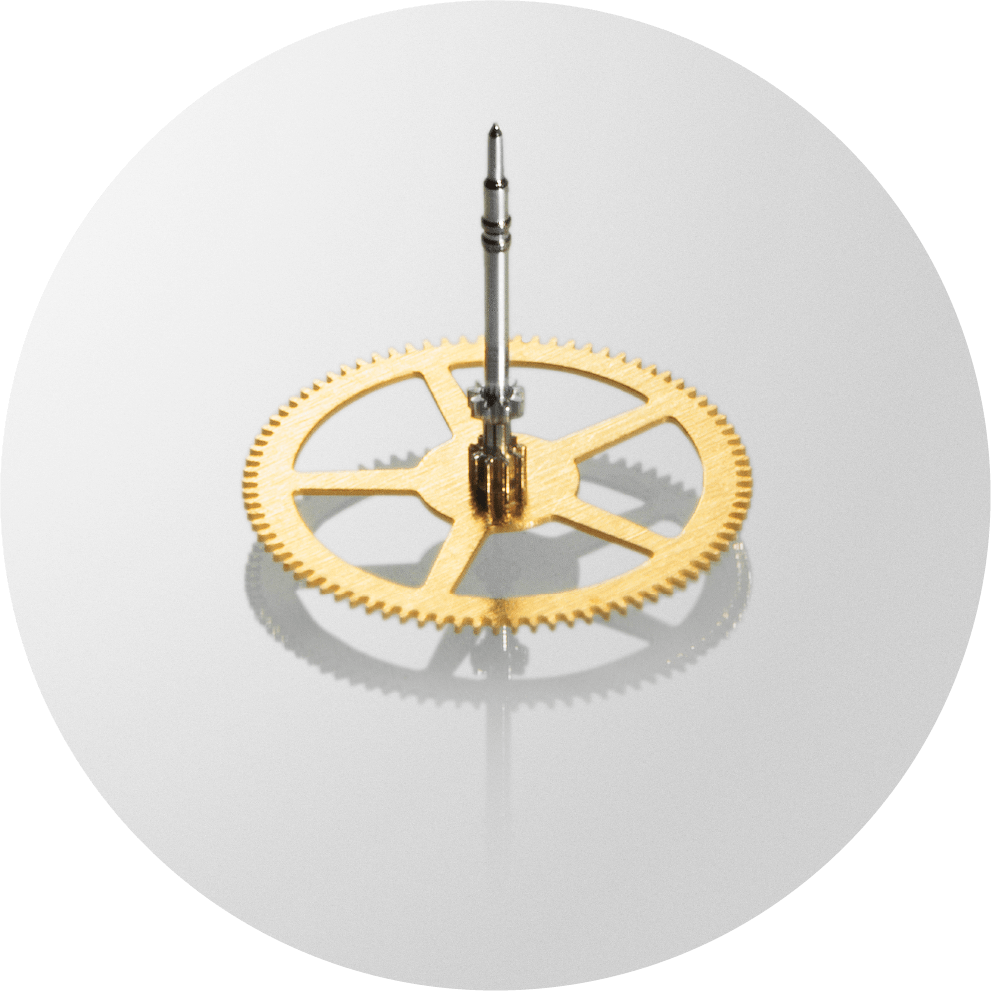

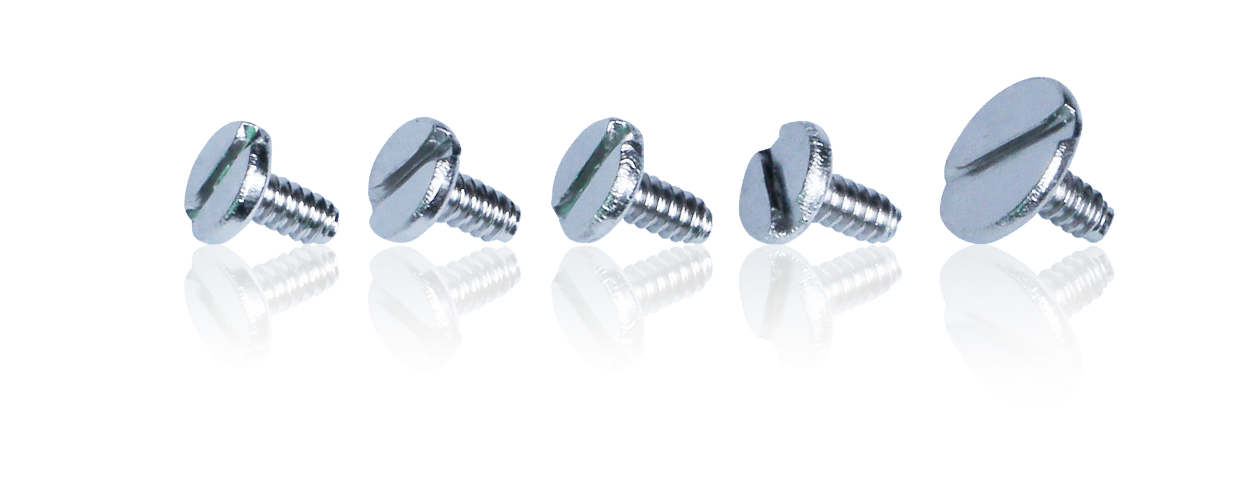

A large variety of screws are used in

the making of a watch.

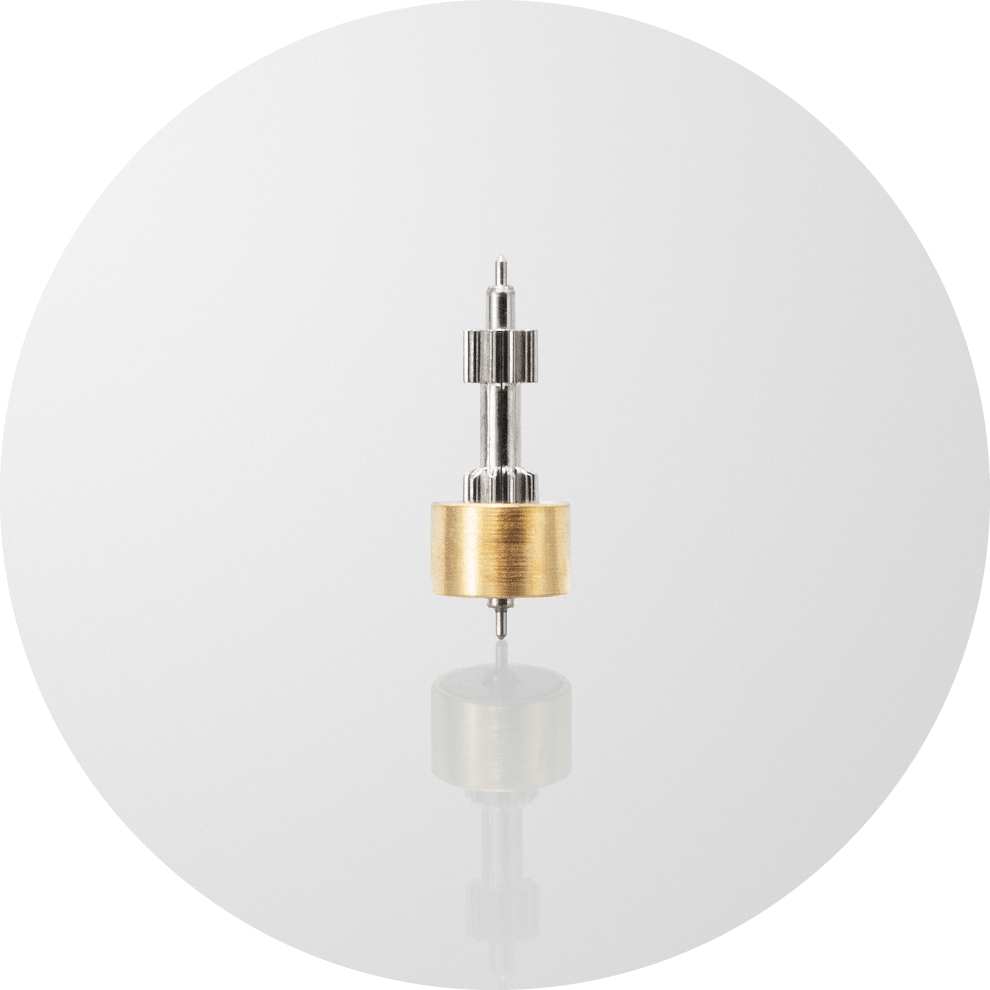

Manufacturing the screws that go

into the movement is far from easy

because they are so numerous, and

they are of many different shapes

and sizes.

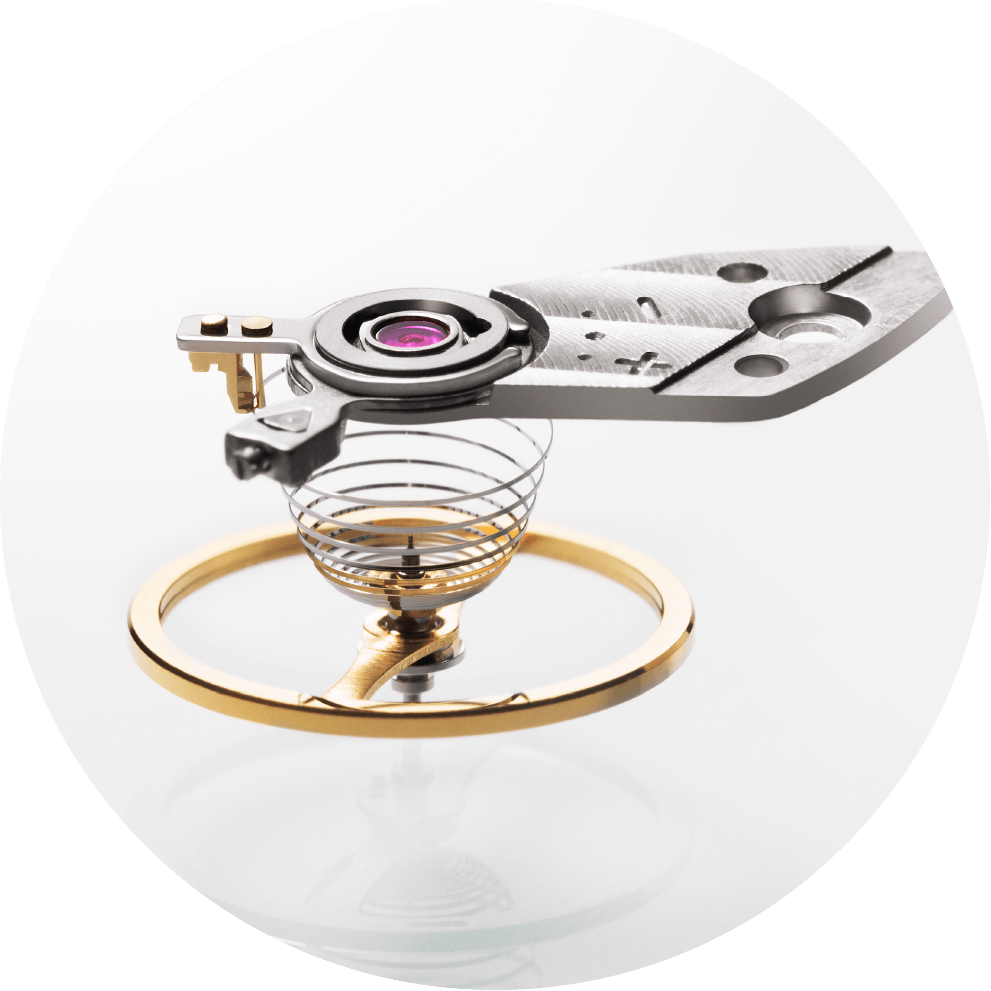

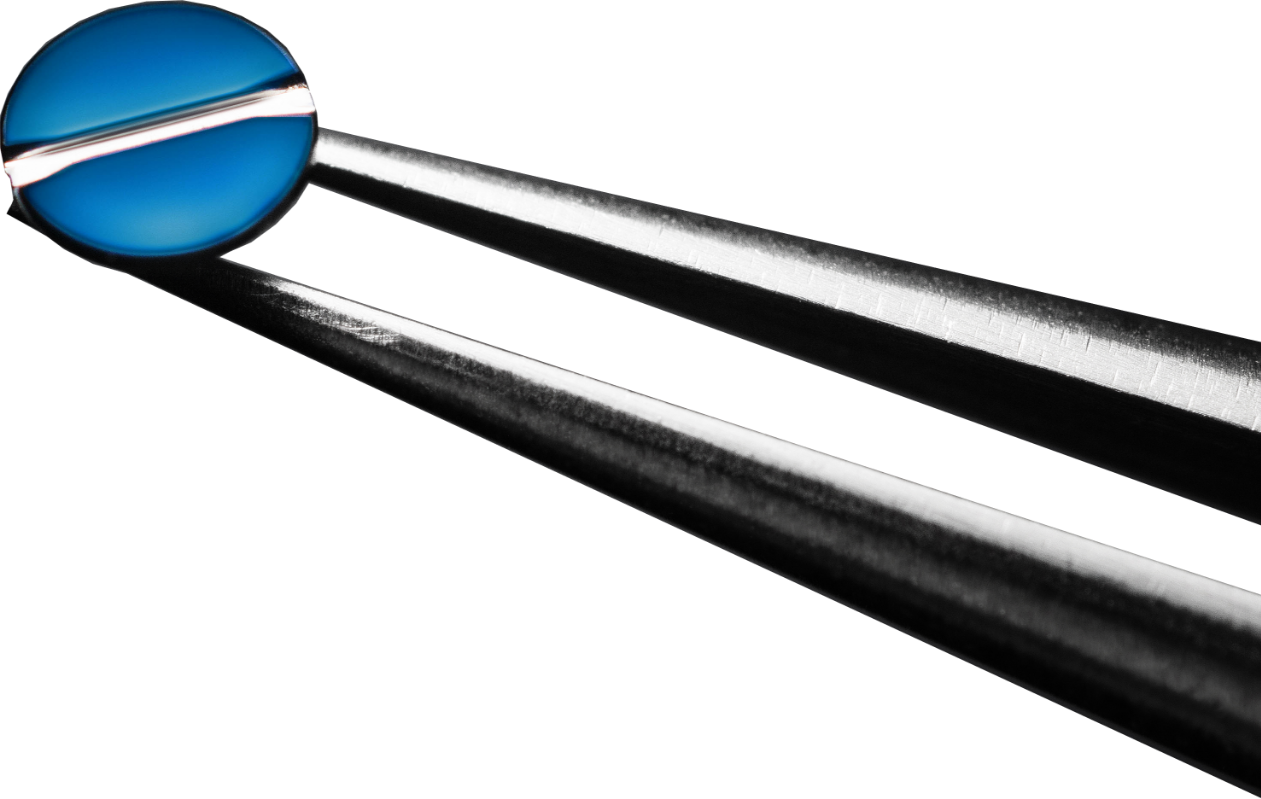

At MIYOTA, we make the screws for our

movements in-house. Thanks to this approach,

we can manufacture custom screws that are

precisely adapted to the many different

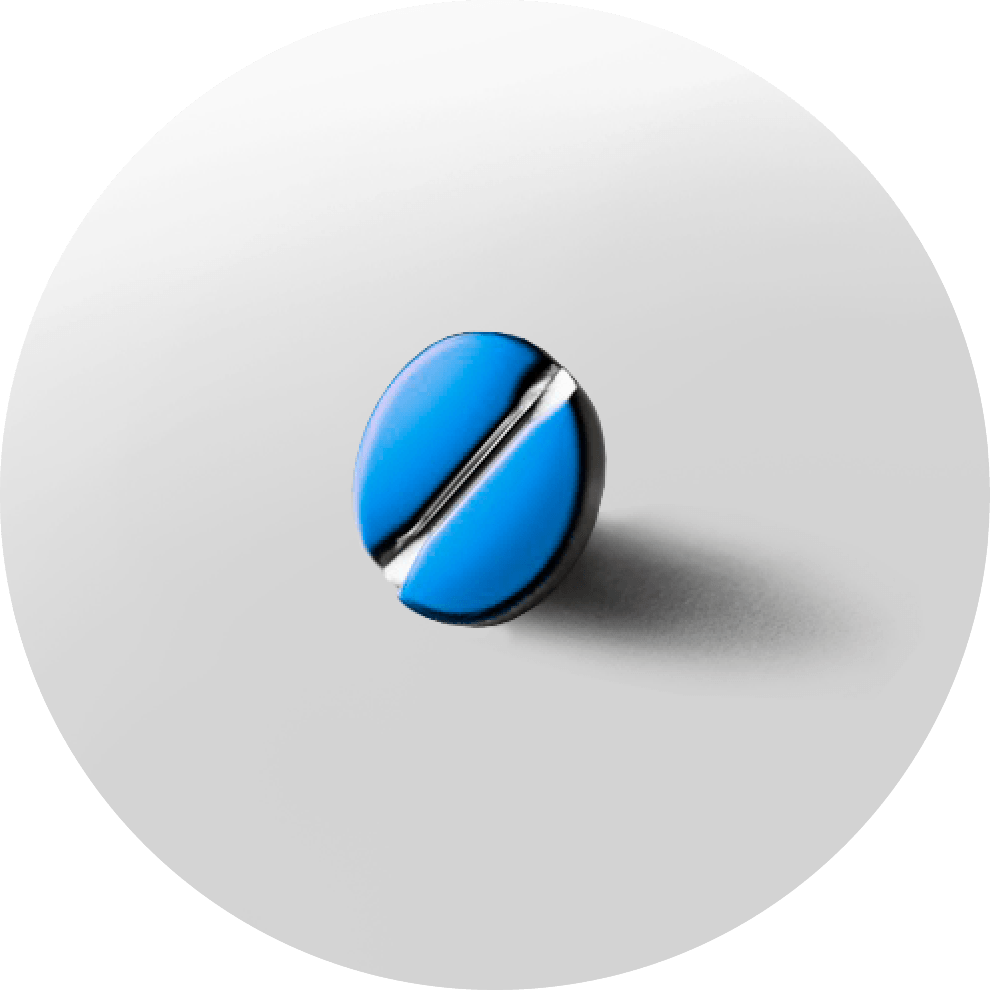

movements we make. We also make heat-blued

screws. These are harder and longer-lasting

than ordinary screws owing to our patented

version of bluing technology.

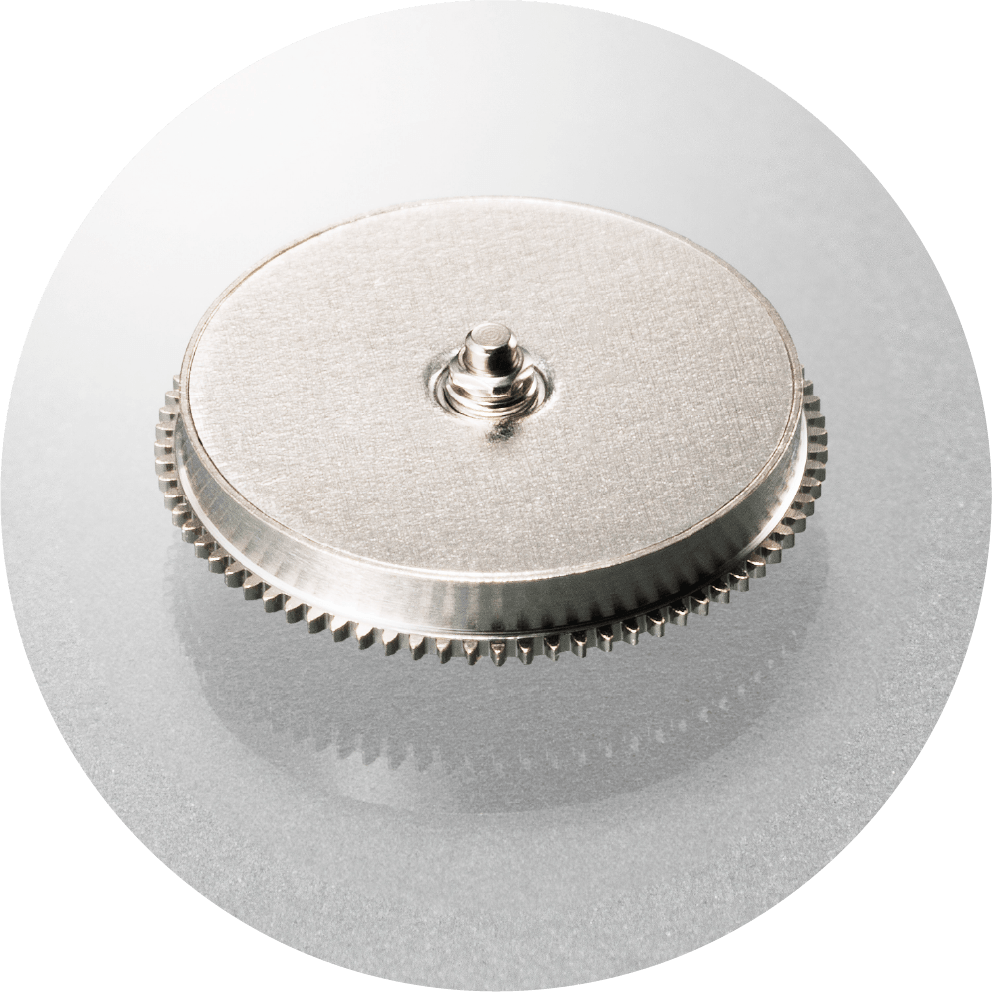

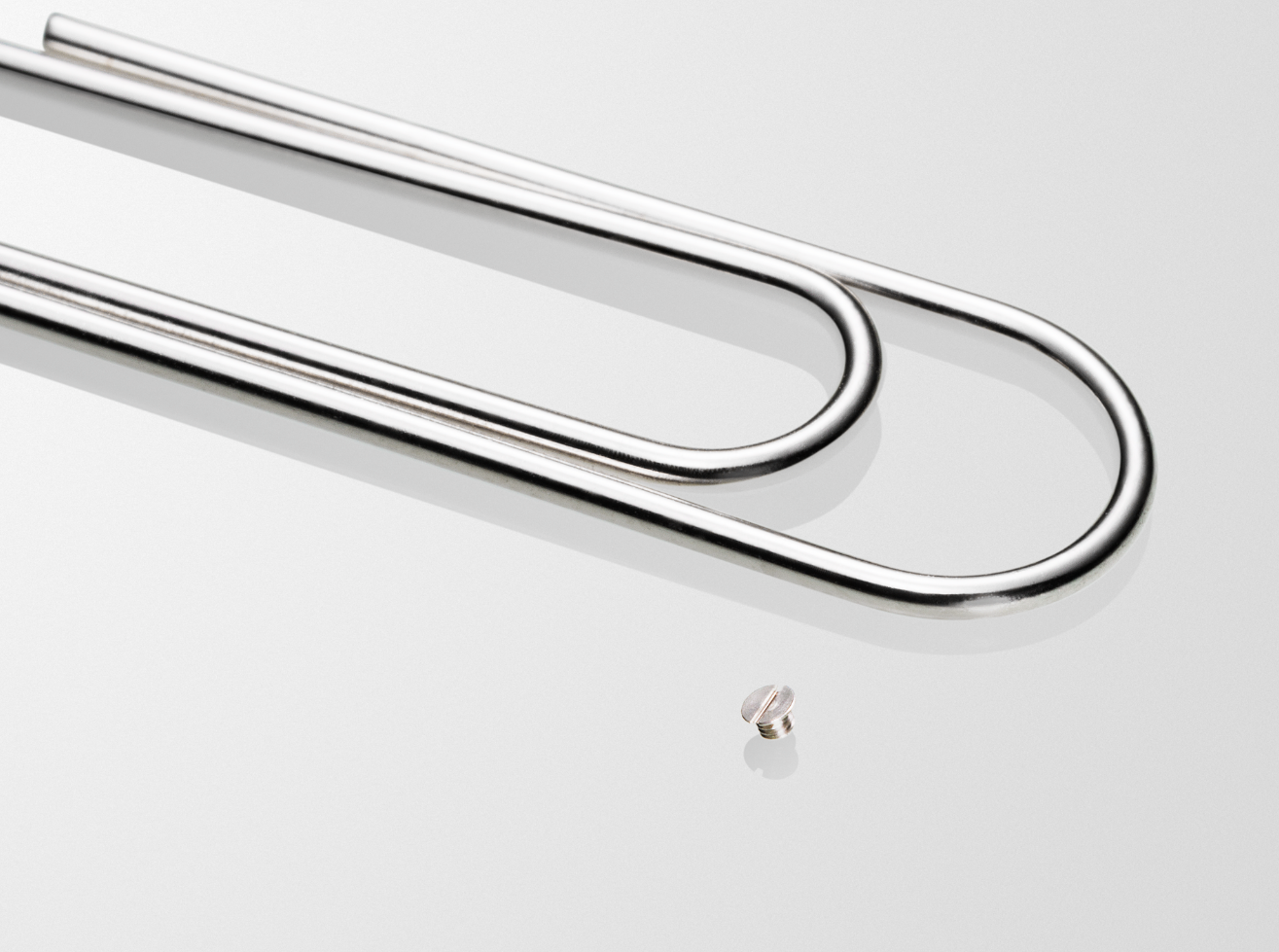

We have a deliberate policy of designing our movements

to incorporate a relatively large number of screws. Why?

Because the more screws there are, the

easier the movement is to disassemble

and repair, resulting in a longer life span

for our customers’ watches. Whatever

component we are making, we always try

to think about these kinds of long-term

“what if” scenarios. It is one of the reasons

behind MIYOTA quality.