50THANNIVERSARYOFTHEMIYOTACALIBER82 SERIES 50THANNIVERSARYOFTHEMIYOTACALIBER82 SERIES

The standard

mechanical movement.

A much-loved long seller.

We want people everywhere to recognize

mechanical watches’ unique worth and appeal.

That’s the aspiration driving the MIYOTA Caliber 82 Series.

Used in a broad range of mechanical watches

since its debut half a century ago in 1975,

the MIYOTA Caliber 82 Series has won the support

of watchmakers and brands worldwide

because of its durability and usability.

As the standard mechanical movement,

the MIYOTA Caliber 82 Series never stops evolving.

EPISODE 1

Breathing new life into

the mechanical watch.

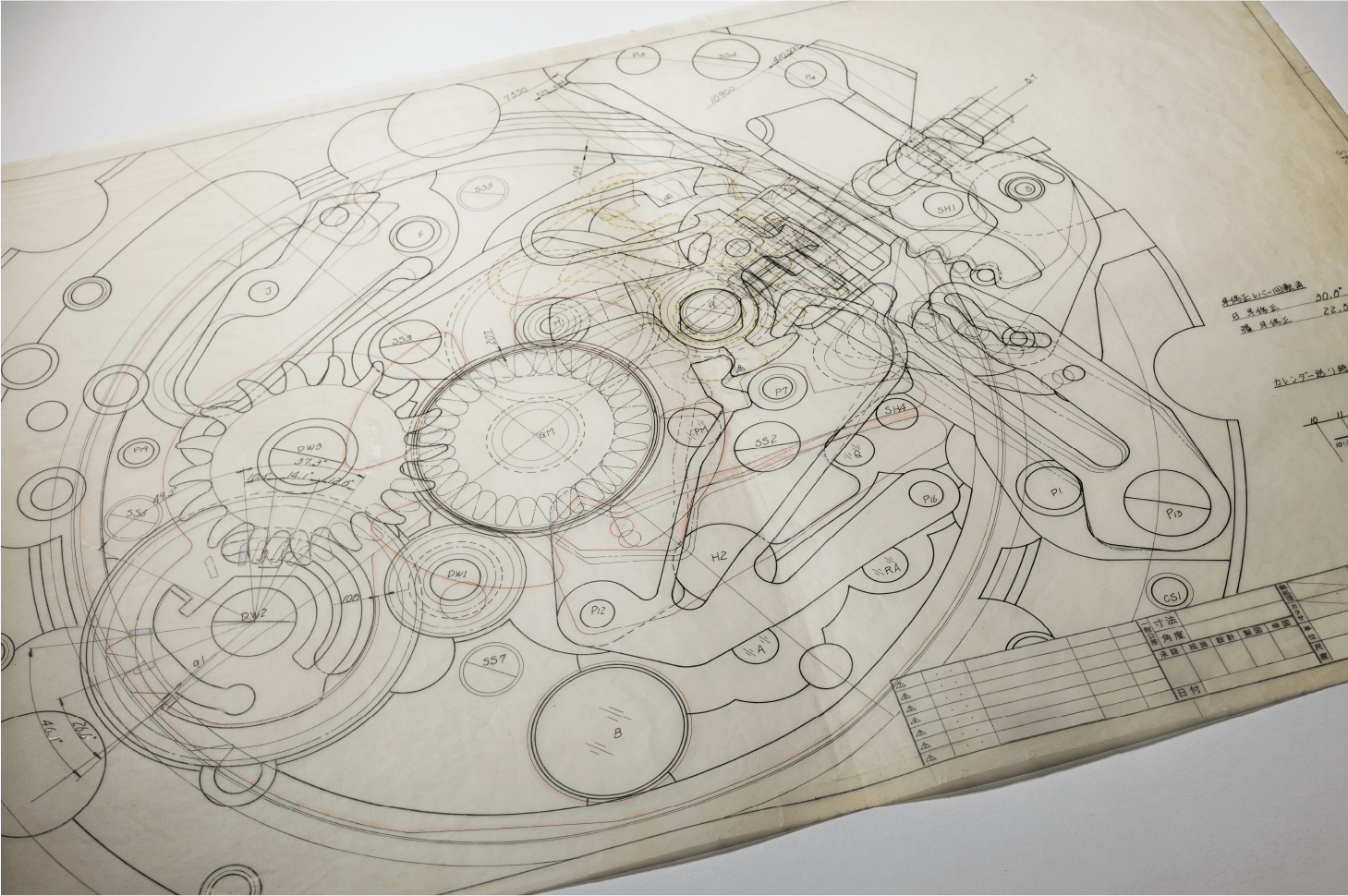

It’s the 1970s. The advent of quartz watches—which have the double advantage of high accuracy and low cost—has sucked the air out of the mechanical watch market with. Many watchmakers opt to switch over to quartz entirely. MIYOTA, however, chooses a different path. Driven by their deep emotional attachment to mechanical watches, our designers continued developing ever more usable mechanical movements with enhanced operating specifications, increased accuracy and greater freedom in case design. At the same time, MIYOTA seamlessly interlinked its factories to optimize everything from the individual components to the overall movement structure. Such is the origin story of the Caliber 82 Series, which was launched in 1975 with one clear mission: to breathe new life into the mechanical watch market.

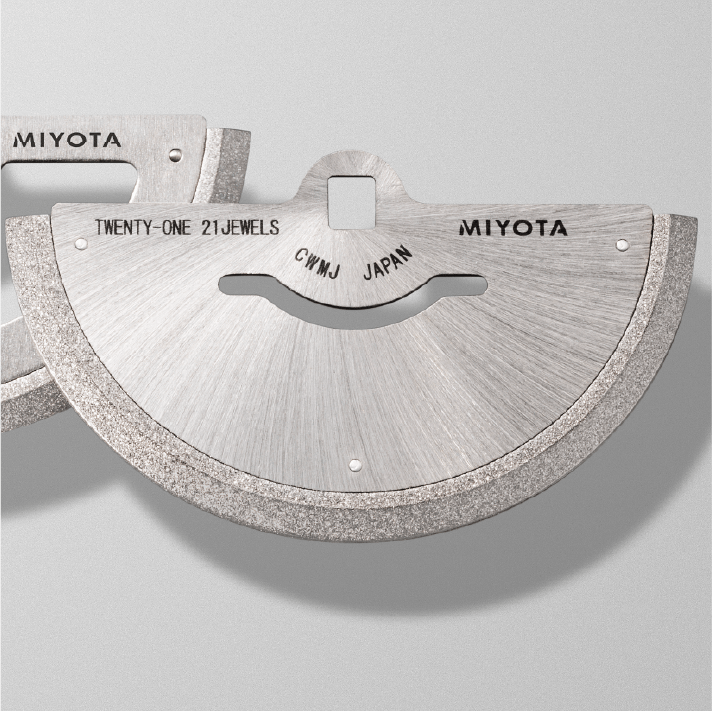

When MIYOTA first started selling movements to third parties outside of CITIZEN, it used to engrave the oscillating weight with the logos of our watchmaking clients. As demand for mechanical watches started to pick up again, however, we instead began engraving them with the logo of MIYOTA as a unitary brand. The MIYOTA Caliber 8205 made its debut in 1986. Thanks to its accessibility and ease of use, it went on to establish itself as the standard for mechanical movements worldwide.

EPISODE 2

A timeless movement’s

popularity explained.

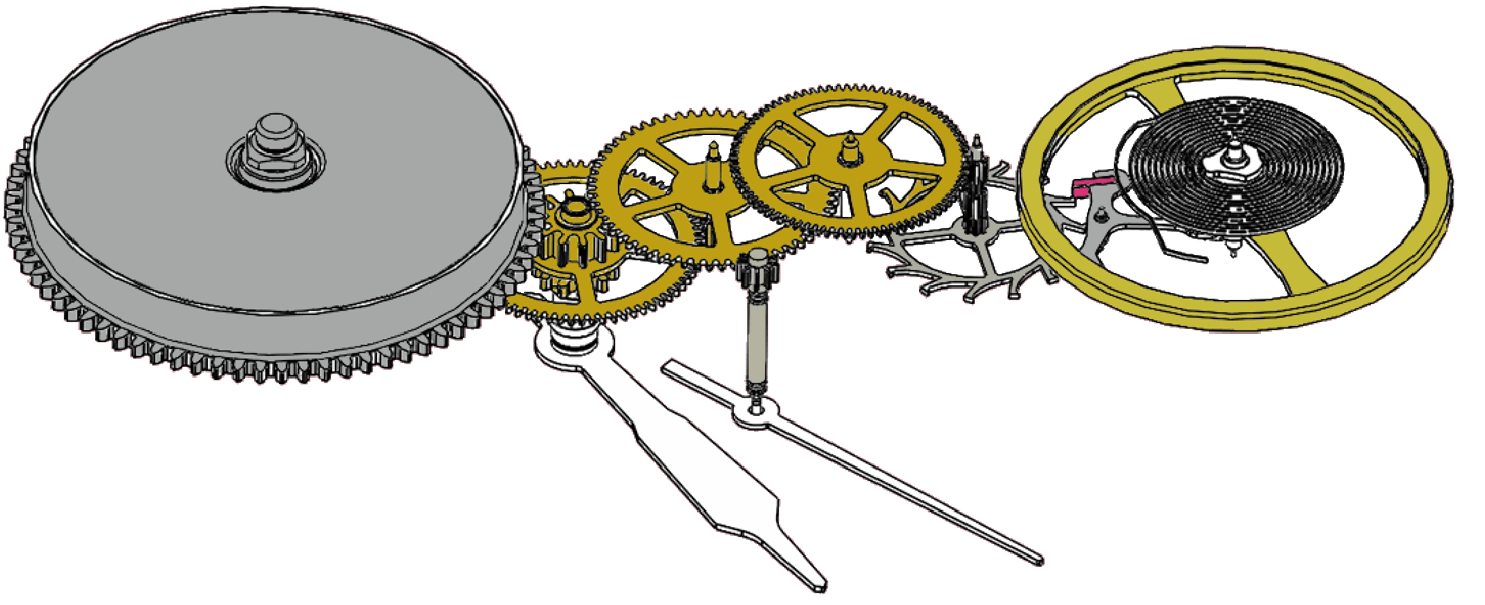

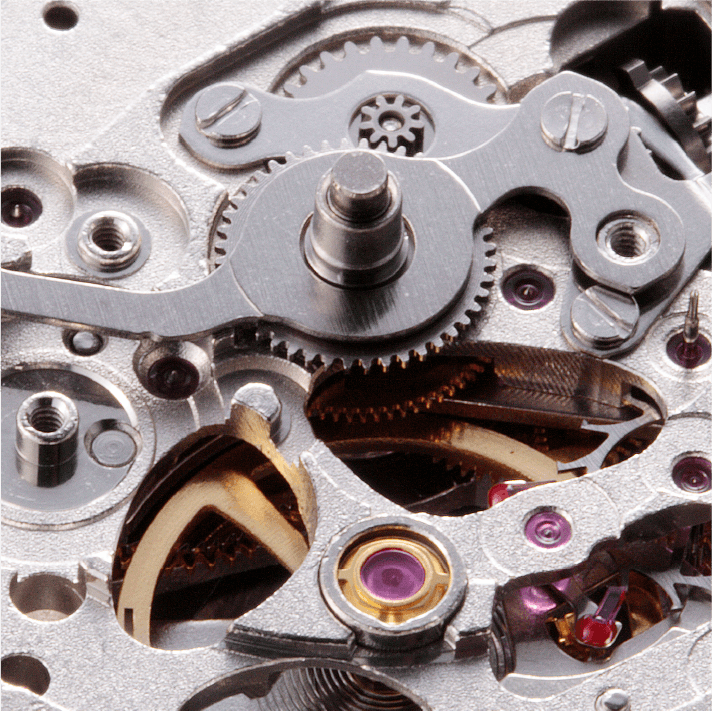

Our aim is to enable the maximum number of people to enjoy their mechanical watches for the maximum length of time. That certainly was the thinking behind our choosing an indirect center seconds configuration for the MIYOTA Caliber 8205. It manages to be simultaneously thin and robust because the gears are distributed across the movement, rather than concentrated in a single position. A low beat rate means not just lower frequency, it also means less friction between components. The result is a mechanical movement that is both durable and usable.

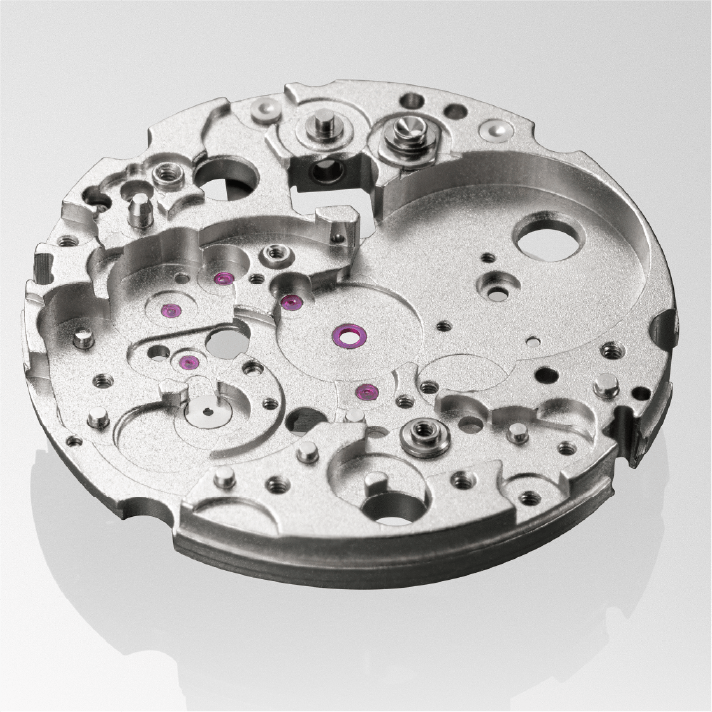

Committed to meeting the demand for high accuracy, ultra-small diameters and unconventional shapes, we didn’t just develop, design and manufacture our own dies and components—we developed, designed and manufactured the jigs we use to make the components too. In fact, the quality of our mechanical movements is the direct result of our obsession with doing everything, no matter how small, in-house. The automated assembly process then maintains that quality, while ensuring a stable supply. That explains why the MIYOTA Caliber 82 Series has been a long seller for half a century—and remains so much loved by watchmakers and brands worldwide to this day.

EPISODE 3

Focusing on quality.

As only MIYOTA can.

There has been a resurgence in the popularity of mechanical watches. While quartz watches, are seen as tools for telling the time, mechanical watches are perceived more as intricate works of craftsmanship that accompany the wearer on life’s journey, transforming time itself into a pleasure. Because of this reevaluation, people now look to mechanical watches for different functions and values.

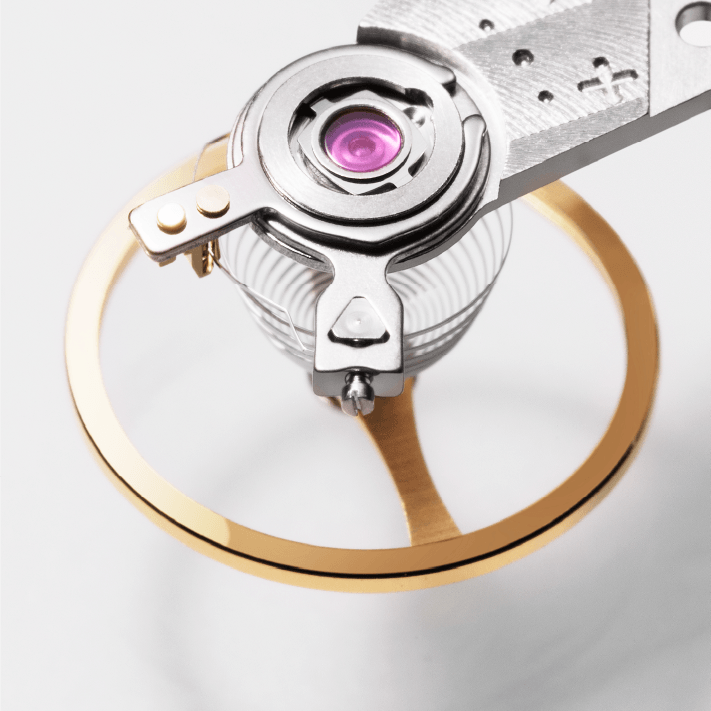

In the MIYOTA Caliber 82 Series, for example, the use of tungsten for the oscillating weight delivers both enhanced rotational efficiency and increased specific gravity. Meanwhile Parashock, MIYOTA’s proprietary shock absorber, protects the balance, which is the heart of the watch. Other improvements to the series include repeated upgrades to the specs of the second hand in all center second movements. Our philosophy of integrated in-house manufacturing, covering everything from component-making through final assembly, enables MIYOTA to implement the most rigorous quality control measures and to improve functions to meet changing needs over time.

MIYOTA Cal.82 Series Commitment

-

Balance cock complete Balances must all be made to a uniform quality level. Our technicians are put through a strict ongoing training regime and work within strict quality-control parameters so they can craft balances of precision and quality.

-

Oscillating weight The oscillating weight is what gives automatic mechanical movements their distinctive visual flair. Using in-house welding machines, we have automated the highly precise welding process. Functional and beautiful, our oscillating weights have an upscale look, efficient winding performance, and a clean, smooth motion.

-

Hand shaft The hand shaft is the shaft on which the watch hands are mounted. Because of our focus on aesthetics, we craft the hand shafts of MIYOTA 2 hands models without a visible aperture at the top end. It’s a typical example of our focus on the crucial details.

-

Main plate MMaking the MIYOTA Caliber 82 Series main plate involves over 50 distinct processes. As the base on which all the movement’s components sit, the main plate must be crafted with extreme precision. MIYOTA has built up significant know-how related to machine tools for main plates over decades.

EPISODE 4

More variants.

More possibilities.

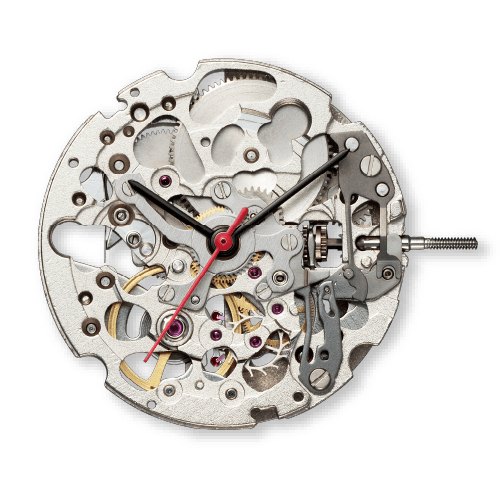

We have developed multiple variants of the MIYOTA Caliber 82 Series to meet watchmakers’ evolving needs. The MIYOTA Caliber 82S line is designed for open heart watches. In a design accent unique to the mechanical watch category, they feature a small window in the dial that shows the balance moving underneath. Meanwhile, the MIYOTA Caliber 8N line is designed for skeleton models that display the whole movement in its complex and intricate glory. Then there is the MIYOTA Caliber 8315 line with a 60-hour power reserve, the longest running time of any of our mechanical movements. Whether it’s design or function, at MIYOTA we never stop looking for ways to extend the possibilities of the mechanical movement.

EPISODE 5

EPISODE 5

The never-ending

quest for better.

An immutable and

undying passion.

Why do mechanical watches continue to enchant and enthrall us? After all, if accurate timekeeping was the only thing people wanted from a watch, then surely quartz could do the job perfectly well? The answer is that—from the sound of time ticking by to the hypnotic sight of the movement’s intricate mechanism in action—mechanical watches offer unique ways of experiencing and enjoying time.

Thanks to our use of CNC lathes and an automated assembly process, the easy-to-use and easy-to-maintain MIYOTA Caliber 82 Series is available at an accessible price point. It has established itself as the standard for mechanical movements because we are continuously making improvements and adding functions in response to customer feedback.

We plan to keep on firing the imagination of the worldwide watchmaking community in the years ahead.

We believe in enabling the maximum number of people to get maximum enjoyment from mechanical watches. Going forward, we will continue our efforts to support and stimulate the creativity of watchmakers and brands worldwide with our high-quality movements